- Home

- Companies

- Silmisa Maquinaria ,S.L

- Products

- Titan Shipyard - Model 700 & 1000 - ...

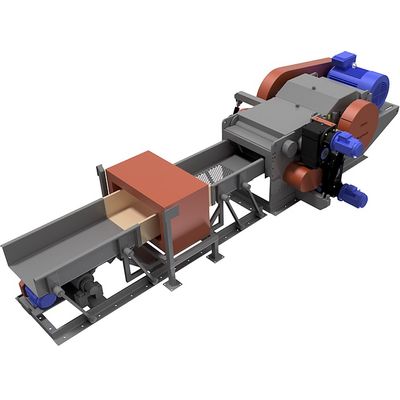

Titan Shipyard - Model 700 & 1000 -Wooden Splinter

Our wooden splinter is a powerful tool designed to simplify and accelerate the splintering process. With exceptional performance and robust construction, this shipwreck stands out for its ability to convert logs, boards, etc. into fast and efficient splinters. Experience the efficiency and power of our wooden splinter and discover how to simplify your splintering tasks while you get exceptional results. Power, security and versatility in a single machine.

Power and efficiency: Equipped with a high-performance engine, our splinter can handle large waste and thick branches with ease. Its powerful cutting mechanism ensures a fast and efficient splintering, reducing the time and effort needed to process the wood.

First of all: Security is essential in a static splinter. These machines often have safety systems such as emergency stop switches, protections in the cutting areas and locking systems to avoid access to the blades while they are in operation. This ensures a safe operation and reduces the risk of injury.

Robust and durable design: A static splinter is built with resistant and durable materials, allowing it to withstand intensive use and adverse conditions. It is designed to withstand the pressure and effort of the continuous splintering, which makes it a long-term investment.

Versatility in size: You can handle a wide range of log sizes. Some are designed for smaller diameter trunks, while others can splinter larger trunks. This provides flexibility in the size of the wood that can be processed.

Ease of use: Our wooden splinter is easy to operate. They have intuitive and accessible controls, which makes it easier for users without previous experience in the wooden splinter.

Low maintenance: These splinters are designed to require minimal maintenance. With proper care and periodic lubrication, they usually run smoothly for long periods of time. This reduces the costs and time spent on maintenance, allowing you to concentrate on your splintering tasks.

- ROTOR (mm): 700

- MATERIAL . . . . . . . . . . . .

- RODILLOS DE ENTRADA SUPERIOR: 2

- RODILLOS DE ENTRADA INFERIOR: 3

- CUCHILLAS: 2-4

- PRINCIPAL MOTOR POTENCE KW: 90/110

- RPM TAMBOR: 650

- ROTOR (mm): 1000

- MATERIAL m/m ENTER: 300 x 1000

- RODILLOS DE ENTRADA SUPERIOR: 3

- RODILLOS DE ENTRADA INFERIOR: 4

- CUCHILLAS: 2-4

- PRINCIPAL MOTOR POTENCE KW: 132/200

- RPM TAMBOR: 600