- Home

- Companies

- Technical Manufacturing Corporation ...

- Products

- TMC Electro-Damp - Model II - Active ...

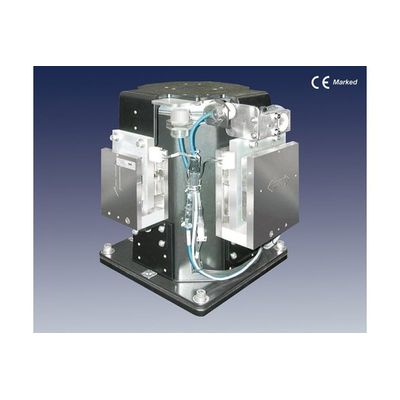

TMC Electro-Damp - Model II -Active Air Vibration Cancellation

Electro-Damp is the first commercial active vibration isolation system designed specifically to increase throughput, resolution, and yield in semiconductor manufacturing applications. The Electro-Damp II is a complete redesign of the original system, adding modularity, digital control, feedforward, high-force/high-clearance actuators, and multiple digital user interfaces specifically designed for use in OEM applications such as microlithography, inspection, and metrology tools.

Semiconductor manufacturing tools place conflicting demands on their vibration isolation system. In response to floor noise, the system must be soft to effectively filter floor vibration from reaching the isolated surface. Simultaneously, the system must be stiff in response to stage forces such that stage motion induces minimal displacement of the isolated surface and settles rapidly.

In addition to employing inertial, active feedback damping, Electro-Damp II uses information feedforward to further improve system response. Feedforward works by taking information from a stage controller about the stage`s position and acceleration, then processes that data to provide force actuation to the payload, greatly reducing stage-induced payload motion. The system can read the feedforward information digitally, as bipolar analog signals, or by reading the output of quadrature encoders. The DC-2000 Digital Controller can also automatically adjust the parameters required by feedforward using a stage test pattern. This makes setup on initial installations, or after changes to the payload, quick and easy.

Electro-Damp II`s modularity allows the system to be used with electronic servo valves alone (for heavy, low-acceleration applications like CMMs), with electromagnetic actuation only (for lighter stages which use high rates of acceleration), or a combination of both for the most demanding applications.

- Six degrees-of-freedom active vibration damping system

- Non-contacting electronic height control

- Digital controller

- Feedforward inputs correct for stage-induced payload motions

- High-force electromagnetic actuators available separately or integrated

- Reduced payload motion and settling time for stage-induced motion

- Higher throughput, resolution and yield

- Modular design allows user ro specify a complete unit or components for ease of OEM integration

- Automatic tuning of feedforward parameters for reduced setup

General

- Settling time : 0.2 s **

- Active degrees of freedom : 6

- Height control accuracy : < 10 µm at sensors

Linear Actuators (horizontal & vertical)

- DC resistance : 5 Ω

- Force constant : up to 12 lb./A | 55 N/A

- Max. continuous force : 25 lbs. | 110 N

- Peak force @ 7 A : 87 lbs. | 385 N

- Electrical time const. : 2.6 ms

- Stroke : 0.25 in. | 6.4 mm

- Transverse clearance : 0.09 in. | 2.3 mm

- Stray field : < 1 G @ 2 in.

- Dimensions (WxDxH) : 2.8 x 6.8 x 4.5 in. 71 x 173 x 114 mm

Valving (active only)

- Valve type : Proportional E/V servo

- Control type : Pressure or air flow

- Max. flow rate : 1.5 SCFM

- Air consumption (4 isolators) : < 2 SCFM (no stage motion)

- - 3 dB response : ≤ 10 Hz typ.

Height Control Sensors

- Type : Non-contacting inductive (eddy current)

- Electronic configuration : Two-wire NAMUR

- Three-wire 30 or 18 mm dia.

- Range : 15 mm nominal for 30 mm wire

- 6 mm nominal for 18 mm wire

- Resolution : < 1 µm

Passive Pneumatic Mount

- Standard capacities : 1,000, 2,500, 3,300, 5,700 lbs. @ 80 PSI

- Damping (10:1) : < 3 s

DC-2020 Digital Controller

- Processor : Dual core:

- DSP @ 150 MHz & Cortex M3 @ 75 MHz

- Analog I/O : 32/24 channels (16/16 bit)

- Sampling rate : 5 kHz nominal

- Front panel : Power switch

- 3-color status LED

- Ethernet RJ-45

- MicroSD card slot

- 2x BNC sockets (each can be input or output)

- 2x USB 2.0 ports (Type B and Micro B)

- FW upgrade button

- Rear panel : Power entry

- Analog I/O sockets

- Pneumatic ports

- Ethernet RJ-45

- 1x USB 2.0

- RS-232 DB 9

- Relay socket

- User interface : GUI via USB or ethernet

- Power : 90-240 VAC, 50-60 Hz, 100 W max.

- Dimensions (WxDxH) : 16.8 x 9.0 x 1.75 in.

- 427 x 229 x 45 mm

- 1 standard RETMA unit

Power Amplifier

- Channels : 8

- Max. current per channel : 7 A

- Type : Linear

- Peak power : 700 W total

- Cooling : Ambient, forced air

- Protection : Resettable fuses, electronic thermal, over current, under voltage

- Operation : Remote or manual

- Dimensions : 1 RETMA rack unit height x 15 in. (381 mm) depth