- Home

- Companies

- Hebei Tobee Pump Co.,Limited

- Products

- Tobee - Model 6x4DAH - Horizontal ...

Tobee - Model 6x4DAH -Horizontal Slurry Pump Bearing Assembly E005M

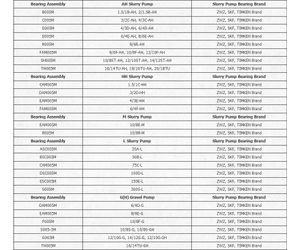

Email: Sales7@tobeepump.com Web: www.tobeepump.com | www.slurrypumpsupply.com | www.tobee.cc | www.hydroman.cn SPECIFICATIONS: Bearing Housing: HT250 Bearing: ZWZ, SKF, TIMKEN etc Shaft: 40CrMo Shaft Sleeve: SS420 Matched Model: AH, HH, L, M, SP(R), G/GH, AF Slurry Pump Bearing Assembly also called rotor assembly, It is a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. It is most important part for drive power unit. The bearing assembly is to connect the slurry pump and motor as a complete pump working system. Its stability will directly affect slurry pump operation and worklife.6/4E-AH and 6/4D-AH Slurry Pump bearing assembly basic part number is E005M, it is the main component of drive end which transmit power to impeller.

Slurry pump bearing assembly has a large diameter shaft with a short overhang minimizes deflection and vibration. Slurry pump bearing assembly has two sets of single row tapered roller bearings which are face-to-face installed in a removable bearing housing, high capacity bearing assembly has one set of double-row tapered roller bearing installed near the slurry pump impeller and one or two sets of cylindrical roller bearing installed near the motor. Standard and high capacity bearing assemblies are dimensionally interchangeable.

Tobee® Slurry Pump Bearing Assembly Module Design:

• Grease Lubricated Bearing Assembly

The grease-lubricated bearing assembly houses a large-diameter shaft in its unique bearing cartridge designed specially for heavy-duty tasks. Due to its compact design, the bearing takes up little space while providing minimum vibration and deviation. Grease lubrication minimizes the possibility of oil leakage and little extra maintenance effort is needed. The rotor is easily adjustable. Users can install several rotors operating in series.

• Horizontal Axially-Split Bearing Assembly

Lubricated by oil, the axially-split bearing assembly features a large-diameter shaft and a short cantilever. It delivers high rigidity, and is unlikely to deform or vibrate even when highly abrasive solids are encountered. The bearing is directly mounted inside the bearing support which can be split into 2 halves along its center line. This mounting method allows for ease of disassembly, inspection and adjustment of bearing. Water cooling system effectively cools down the hot bearing, greatly improving its use life.

• Cartridge Type Oil-Lubricated Bearing Assembly

Spacious cartridge design allows for the installation of a large-diameter rotating shaft. Built specially to handle heavy-duty tasks, the metric size bearing is lubricated by thin oil. Users can install several bearings operating in series. Compact design and high reliability are 2 major benefits of this bearing for its end users.