- Home

- Companies

- TOC Systems, Inc.

- Products

- StarTOC - TOC Recovery System with Dual ...

StarTOC - TOC Recovery System with Dual Ozone and UV Technology

StarTOC Dual Method Ozone / Hydroxyl Radicals + UV / Heated Persulfate offers the highest oxidation potential to assure complete TOC recovery in the most difficult of samples. This Dual Method satisfies the most challenging of applications and is the clear choice of performance-oriented users, who require the highest level of precision in analysis.

- Microsoft Windows Touch Screen Computer

- Dual NDIR Detectors Available

- Automatic Carrier Gas Flow Controller

- 2 Level Alarms; 1 Master Fault Alarm

- 4-20 mA Outputs

- RS-232/485 Outputs

- Network Ready

- Auto-Calibration/Auto-Clean

- Benchmark/Auto-Validation

- Correlated BOD/COD

- Multi-Stream Analysis

- NEMA 4X/IP 66

- Correlated BOD/COD

- Automatic Multi-Range

- Multi-Stream Analysis

- 485 Output

- Digital Sample Injection

- Dual Oxidation Methods

- Ozone/Hydroxyl Radical

- UV/Heated Persulfate

- Patented 3-Stage Reactor

- Best Oxidation

- Most Accurate

- TOC-TRUE Analysis

- DualNDIRs

- Truly Continuous

- Touchscreen

- VGA Color

- Network Ready

- Paperless Chart Recorder

- PCMCIA Slot

- Solid State Data Storage

Because neither Ozone/Hydroxyl Radical nor UV/Heated Persulfate can fully oxidize all organic carbon compounds, StarTOC Dual Method was introduced to fully satisfy demands for measuring the total organic carbon in the most difficult industrial samples. Rugged FRP Enclosure allows direct outside installation and integral heating, cooling and purging, without requiring additional costly shelters.

- Most Accessible for Service

- No Local Repair

- Parts Exchange Service Policy (overnight delivery of replacement modules)

- Oxidizes particles up to 3 mm in diameter. (No sample valves to clog or jam)

- Rugged FRP Enclosure allows direct outside installation and integral heating, cooling and purging, without requiring additional costly shelters.

Features & Benefits:

A single package, sample system fully integrated with the analyzer assures proper overall system operating conditions

-AND-

Asingle source of total analytical responsibility, accountable to project management for its sucess.

Utilization of an onboard Windows CE computer allows direct networking. Central control of analyzer operation and data management are easily facilitated.

Difficult industrial samples requiring accurate TOC analysis with minimum maintenance.

- Standard Method 5310 C/D

- EPA 415 1

- EPA 9060

- ASTM D 4839-88

- ASTMD 4778-88

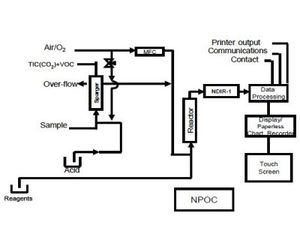

"NPOC" (Non-Purgeable Organic Carbon) mode is preferred for accuracy when no volatile organics are in the sample. Pump (P-1) delivers the sample to the sparger, where it is mixed with acid by pump (P-3) to lower its pH to approximately 2.0. At this pH. the inorganic carbon in the sample is converted to dissolved C02 and is stripped (sparged) from the sample by air/O, and vented to atmosphere, along with any purgeable/ volatile orqanics. The carbonate-free sample is drawn from the sparger by pump (P-2) and delivered to the Reactor, where the remaining NPOC is oxidized to C02. which is measured by the NDIR (Non-Dispersive Infrared Analyzer) as a direct correlation of NPOC in the sample. NPOC is often erroneously reported as "TOC".

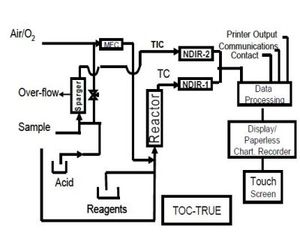

TOC-True mode is the preferred method of use if any volatile hydrocarbons are present in the sample, which would be lost in the Inorganic Carbon removal sparging stage in an "NPOC" analysis. The TOC-True method measures both TC (Total Carbon) and TIC (Total Inorganic Carbon) for a more accurate and complete analysis of the total organics in the sample, including the purgeable/volatile organic carbon. By subtracting the TIC from the Total Carbon in the sample.

all species of organic carbon are measured, not just the NPOC.

Benchmark`21 is the validation technique, whereby on command a chemical calibration standard is automatically introduced to the analyzer and the response is compared to the previous analyzer calibration. If the response falls within a certain specified limit, the computer/output indicates "Benchmark Passed". If the response falls outside specified performance limits, either a "Maintenance Request" or a "Fault" alarm is activated, depending on preset tolerances. Thus, in cases of process spills, when the analyzer performance is questioned. Benchmark can rapidly and automatically validate analyzer performance. It eliminates time consuming and unnecessary recalibration cycles, which take the analyzer out of service just when it is most critically needed. Benchmark may be on-demand, or operator programmed for designated day and time activation on a repetitive basis.

Auto-Cal and Auto-Clean utilities are also included in this option p/n 18039-1.

The NDIR C02detector uses a solid-state, dual-wavelength system with a single borosilicate glass sample cell that requires no wall reflectivity. There is a reference and a CO, specific detector in the sample path. Use of the true zero filter eliminates water vapor interference and the requirement for chemically removing acid gases prior to detection. An infrared source is cycled on and off to avoid mechanical choppers required in alternate NDIRs. The StarTOC NDIR has no moving parts.

Automatic gain control (AGC) is employed during the reference/sample cycle to compensate for such factors as NDIR source deterioration, dirty optical windows, and detector gain changes. When the AGC level reaches a predetermined threshold, the output alerts the Operator to check the NDIR . Malfunctions of major NDIR components are detected as an alarm, providing fail-safe operation. Signal detection is completely synchronous and . because of the differential technique of ratioing the Zero and C02 outputs, zero drift is virtually eliminated. All critical optics are protected by sapphire windows. The sample cell can be easily removed and the windows cleaned within 15 minutes, without realignment or the use of any tools.

This absolute measuring, dual-line spectra comparison NDIR provides simple, direct measurement of all C02 contributing factors (including background) for a true and accurate calibration and precisely offsets these effects for very accurate TOC determinations. The consequences of water vapor interferences in low-level precision TOC analysis are avoided.

Nominal at 25°C. Subject to custom application requirements.