Sequoia Global, Inc.

Sequoia - Transformer Oil Recycling Technology

Hydrogenation in combination with vacuum drying and filtration is the most complete and advanced process technology for recycling of waste transformer oils. In the Hydrogenation process, hydrogen gas reacts with sulfur, nitrogen, chlorine and other unsaturated compounds present in waste transformer oil, producing a water-white, stable product with low sulfur concentration and superior insulating properties.

Most popular related searches

transformer oil recycling

oil recycling

waste conversion

oil recycling system

recycling system

waste oil

chlorinated compounds

wastewater disposal

oil waste

dry filtration

Sequoia’s technology for transformer oil recycling

- Sequoia understands how to preserve the desirable inherent characteristics of naphthenic oils during hydrogenation process and target only the undesirable compounds in the spent oil.

- Sequoia’s hydrogenation technology will almost completely destroy carcinogenic organic chlorine compounds such as PCBs (Polychlorobiphenyls) often present in waste transformer oils.

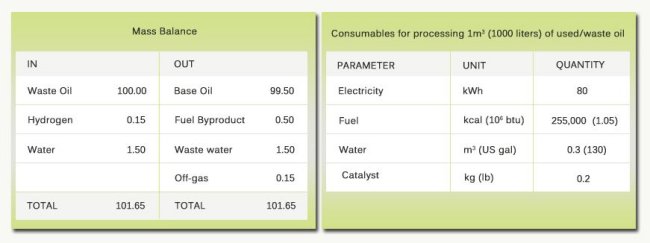

- The cost for electricity, fuel, water, wastewater disposal and chemicals will be $10-20 per m³ (US$ 0.04-0.08 per US gallon) of used transformer oil processed.

- Direct labor will be 8-10 persons.

- The land requirement for a fully integrated facility will be about 1 acre (4000 m²).