Bema A/S

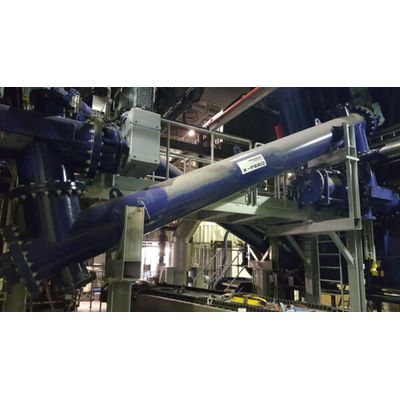

Bema - Model 22760 -Transport System for Coal and Biomass

FromBema A/S

Transport system for coal and biomass material: 3 pipe conveyors transport from one silo system to another: Extraction screw in bottom of the silo. Transportation/lifting screw. Feeding screw into the receiving silo system. All 3 screw conveyor solve a specialised transportation demand.

Most popular related searches

screw conveyor

wear plate

sliding valve

mass flow

recycling system

pipe conveyor

screw bottom

screw conveyor system

recycling conveyor

conveyor system

During design, the demand have been solved:

- Pressure resistance up to 10 barG. FEM analysis of the houses have been performed

- Gear motor design prepared for frequency control. It is possible to change the mass flow instantly (the gear motors coupled together)

- Risk analysis of the complete screw system

Features:

- All inlets and outlet manufactured with bolted flanges

- Service openings (pressure tight) implemented

- Wear resistant plates in critical areas inside the housing

- Delivered with slide valves to close the transport system during non-operation

Manufacturing details

- Manufactured in carbon steel

- Surface treatment - painted according to customer specifications

- Screw flights manufactured in Hardox steel

- Hardfacing applied in wear exposed areas

- Product type: Screw conveyor

- Industry: Power plants

- Transported material: Biomass

- Applied steel in product Carbon steel, Hardox plate, Wear plate

- Surface treatment: Carbon steel – painted