- Home

- Companies

- Suzhou Jono Environmental Technology ...

- Products

- JONO - Trommel Screen

JONO - Trommel Screen

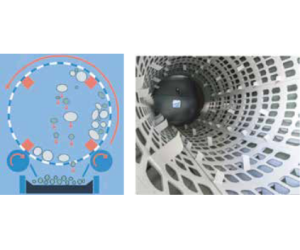

Trommel screen is one of the early products of JONO. It is highly praised by customers for its excellent manufacturing, strong impact-resistance as well as the smooth and silent working process. In recent years, according to the needs of customers, JONO has upgraded the technology and has launched new products such as high-speed trommel screen, 3D trommel screen, trommel screen with super-large diameter and so on.

The Trommel screen rotates the cylinder so that the scattered waste can pass through screen hole of the plate. By doing this, the material smaller than the screen hole is separated from the material larger than the screen hole, which is convenient for the subsequent treatment. Trommel screen is widely used to screen all kinds of waste.

Trommel is installed in a small angel with the input end a little higher than the output end.After having entered into the drum,the material moves along with the drum`s rotation.During the rotation and the moving forward,the small sized material drops through the screen holes,the big sized material will be discharged at the discharging chute at the end.This rotation can make sure the material go through enough holes to greatly optimize the separation effect.

- Drum diameter size: Φ0.8—φ3m (can be customized

- Drum length: 3—12m

- Drive unit: Gear motor 7.5-74kw

- Drum speed: 10—23r/min

- Ambient temperature: 0°C— ?45°C

- Voltage: 3×380V±5%/50 Hz

- Control cabinet: Detached(can be integrated)

- Power control: Frequency converter

- Screen unit: 05—

- Screening rate: 80%—95%

- Input size: ≤1000mm

- Throughput: 10—150m3/h (depending on the material and screen size)

- A variety of models are available.

- Shape of the Bag-opening Trommel Screen: circular sieve drum, which using multiple groups of axial skeleton structure that made of carbon steel to ensure the structural strength and reduce self weight of the equipment.

- The sieve plate is made by bending Q345B (16Mn), which has good wear-resisting performance and guarantees the service life of the sieve plate. The sieve surface adopts the form of circular sieve hole and triangular arrangement, which can meet the requirements of the sieve plate strength and meanwhile ensure the maximum number of sieve holes to improve screening efficiency.

- The outer ring of roller is covered with wear-resistant rubber, which can ensure its durabilityjmprove transmission efficiency, reduce roller track wear and running noise. The outer circle tolerance of the rubber should be within ±1 mm to ensure the smoothness of the cylinder track.

- The reducer motor and drive wheel are connected by cross universal coupling, which is stable and reliable, and can play the role of overload protection.

- The sieve hole can be circular or square (special sieve hole can be designed according to the material

- situation).

- The cylinder is made of high-quality carbon steel. Holistic processing of rolling ring makes the coaxiality of the equipment within design range, stable operation and good tightness of the equipment, which can effectively reduce dust from further diffusion.

- An inspection port is set outside the sieve body for convenient maintenance and cleaning.

- The equipment feeding and discharging chute is designed according to the site and material conditions.

- Special bag opening knives with high efficiency can be designed according to the demand of the inside barrel.