- Home

- Companies

- Buhler Group

- Products

- Buhler - Model LBCB - Trough Chain ...

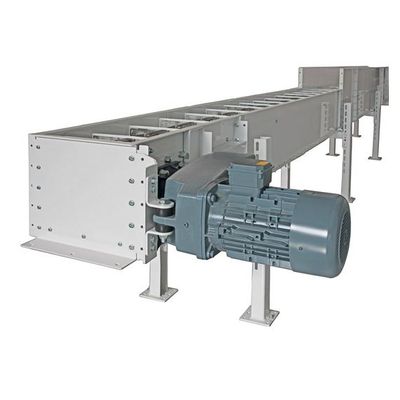

Buhler - Model LBCB -Trough Chain Conveyor

Our chain conveyor LBCB sets standards in versatility and performance. The wide range of its accessories allows the safe and gentle handling of grainy and floury products.

A versatile chain conveyor

With this machine, we use a bottom-up approach, so we can design every chain conveyor according to customer specifications. In this way, you get the optimal conveyor for the intended application field.

Our conveyor features plastic scrapers on every plate link and special rubber cleaning vanes, so less product will adhere to the trough. In this way, even the most stringent sanitation standards can be met.

Best operational reliability

Safety equipment such as an overflow device in the driving station and an optional zero-motion monitor in the tensioning station enable high plant availability.

The chain conveyor LBCB features a number of chain and bearing options. The system is modular and uses standardized machine components. With these characteristics, the conveying system can be configured flexibly and according to customer specifications.

The conveyor’s features assist you in maintaining even the most demanding standards in hygiene and sanitation. They include chain wheels with dirt grooves, outlet flaps under the trough, plastic scrapers attached to every chain link, and rubber cleaning vanes spaced at greater intervals. The tensioning station is designed to minimize residue buildup.

Our chain conveyor LBCB is constructed with a zero-motion monitor at the tensioning station. This device detects chain ruptures indirectly via monitoring the speed of a non-driven shaft. Another feature to protect the plant against failure is the overflow flap in the driving station. This stops the machine as soon as product piles up in the driving station.