Vermeer - Model TG5000 -Tub Grinder

The TG5000 is an ideal combination of innovation and power. Powered by one of two turbocharged CAT Tier 3 engine options, it features a hydraulic tub drive chain tensioner that automatically adjusts the chain while operating as well as the exclusive Vermeer duplex drum, which offers optimum cutting performance and simplified maintenance. Add on the PT tech wet clutch with microprocessor control to automatically limit torque when necessary. Optional climate-controlled cab and grapple loader makes the TG5000 a one-man operation to help reduce labor costs and increase jobsite efficiency.

- Standard radio remote controls allow most machine functions to be operated from the convenience and comfort of a mobile loader.

- Handle more material with the continuous undermill conveyor system that resists clogging.

- Reduce quantity and distance of thrown objects with a low profile tub cover and rotor deflector.

- Tub tilt over 90 degrees allows easy servicing of hammermill and screens, reducing maintenance time in the field.

- See your Vermeer dealer for comprehensive service and genuine Vermeer replacement parts.

Building on more than a decade of grinder research and development, the Vermeer TG5000 tub grinder packages innovation and power for large land-clearing projects and organic/wood waste processing applications.

A powerful Cat six-cylinder turbocharged Tier 3 diesel engine provides exceptional power and fuel economy. Two engine options are available: Cat C15, 540 hp (403 kW) or Cat C13, 440 hp (328 kW).

For ease of travel from jobsite to jobsite, the TG5000 is equipped with super single tires which provide increased flotation. Plus it is designed with 11" (28 cm) of ground clearance for better transport and off-road maneuverability.

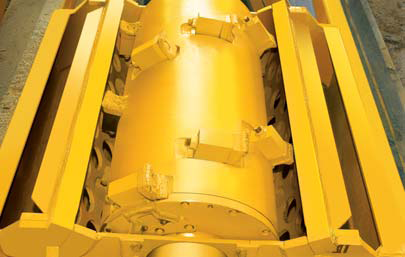

The patented Duplex Drum cutting system decreases daily maintenance while increasing the life of major wear components by being able to reverse the cutter blocks, hammers, and center section of the drum.

Control panel. The control panel display of the microprocessor and CAT engine systems, provides real time performance data. The control panel also provides full instrumentation and diagnostic gauges for monitoring hydraulic systems and troubleshooting. The panel is located under the Falling Object Canopy, which helps protect the operator from falling debris.

Hydraulic tub drive chain tensioner. A hydraulic cylinder increases tension on the drive chain when the tub rotation circuit is under load, reducing periodic adjustments. Continuous tub chain sprocket provides positive drive at any load.

Duplex Drum. The patented Duplex Drum cutting system offers optimum cutting performance and simplified maintenance. In addition, it offers the latest technology in hammer design and replacement procedures in the industry. Maintenance time is reduced due to easy hammer and cutter block changeout. Hammers and cutter blocks are reversible, therefore nearly doubling hammer life.

Ground clearance. A tandem or triple axle suspension with super single tires provides flotation and 11" (28 cm) of ground clearance for better transport and movement in areas where soil conditions are unstable. The enhanced clearance also provides protection of components under the machine, such as brake canisters and axle components, by keeping them up and out of the way of debris that is commonly found on jobsites.

Optional PT Tech clutch. Push-button engagement reduces the chance of operator error, and allows the operator to engage the clutch via remote, cab, or ground control station. Clutch engagement is maintained by oil pressure, eliminating the need for clutch adjustment and also provides torque limiting protection. What’s more, the clutch is backed by a 1-year/1,000-hour limited warranty.

Ergonomic cab enclosure and cab controls. The optional loader cab pivots with the loader, allowing greater visibility and reducing operator movement during normal working conditions. Filtered and pressurized incoming air, heater, and air conditioner provide greater operator comfort. Once the machine is started from the ground control station, virtually all operations can be controlled from the cab.

Continuous undermill conveyor system. Designed to handle large volumes, the 36" (91 cm) wide conveyor belt has a maximum speed of 640 fpm (195 m/min) and a height capability of 14" (4.3 m).

Thrown Object Restraint System (TORS). The patented conical TORS has a smooth underside for increased life and better material flow while reducing the quantity and distance of thrown objects when positioned over the tub.

Optional loader. With a 27` (8.2 m) reach and continuous rotation multi-tine grapple, the loader has the ability to lift up to 3,500 lbs (1,588 kg) at full reach.

General

Approximate weight: 45,000 lb (20,412 kg)

Weight at axles (estimated): 32,000 lb (14,515 kg)

Length (transport): 38.8` (11.8 m)

Length (conveyor unfolded): 60.3` (18.4 m)

Width (transport): 8.5` (2.6 m)

Height: 13.1` (4 m)

Tongue weight: 13,000 lb (5,897 kg)

Fuel tank capacity: 195 gal (738 L)

Drive Line

Dive line: Dana 1810

Option 1: Electronically controlled HPTO-14 hydraulic actuated wet clutch system

Option 2: Electronically controlled HPTO-12 hydraulic actuated dry clutch (with C13 440 hp or 328 kW)

Controls

Radio remote control with 50 channels Functions: Tub rotation, forward and reverse, tub auto rotation, on and off, engine throttle, conveyor height, engine emergency stop, clutch on and off, side-mounted ground control station with falling object canopy

Trailer

Axle rating: 20,000 lb (9072 kg)

Axle: Tandem or triple axle under-slung spring suspension

Tires: 445/50R22.5 super singles

Brakes: Spring applied, air release

Engine

Model:

Engine option 1: CAT C13 Tier 3

440 hp (328 kW)

Engine option 2: CAT C15 Tier 3

540 hp (403 KW)

Aspiration: Turbocharged after-cooled

No. of cylinders: 6

Max torque:

Engine Option 1: 1,483 ft-lb (2,011 Nm)

Engine Option 2: 1,819 ft-lb (2,466 Nm)

Electrical system: 24 volt

Fuel consumption rate @ full load:

Engine option 1: 23 gph (85.6 L/hr)

Engine option 2: 27 gph (102 L/hr)

Approximate operating range:

Engine option 1: 8.6 hrs

Engine option 2: 7.2 hrs

Tub

Pump type: Gear

Inside diameter of bowl: 8.1` (2.5 m)

Outside diameter of flares (top): 12.25` (3.7 m)

Depth: 5` (1.5 m)

Loading height: 10.6` (3.2 m)

Wall thickness (T1 steel): .25" (.6 cm)

Drive type: Continuous sprocket on tub using 120H roller chain

Tub agitators: 4

Tub rollers (qty.): 8 carrier and 8 guide

Tub Cover

Hydraulically positioned

Hydraulically locked for operation and transport

Duplex Drum

Feed opening: 24" x 47" (61 x 119 cm)

Number of hammers: 8

Number of cutters: 16

Cutter block types: block style single bolt wide 3" x 3.5" (8 x 9 cm) 2 bolt narrow 2" x 3" (5 x 8 cm)

Center retention pin: 2" (5 cm) diameter

Number of wipers: 2

Screens

Number of screens: 2 - 3/4" A/R 400

Anvil: T1 welded to screen

Screen area: Combined screen area 2,714 sq in (6,894 sq cm)

Custom screen sizes available

Discharge Conveyor

Length: 24` (7 m) from rear of machine

Width: 36" (91 cm)

Idler roller: Crowned steel design with lagging and taperlock

Belt speed (max): 640 fpm (195 m/min)

Load Height:

Minimum: 9` (2.7 m)

Maximum: 14` (4.3 m)

Air Compressor (Optional)

Brand: Ingersoll Rand

Motor: 12.5 hp (9 kW) Kohler

Max PSI: 175 psi @ 6.4 CFM (12.3 kg/sq cm @ .18 CMM)

Tank capacity: 30 gal (114 L

General (With Loader)

Approximate weight: 62,600 lb (28,395 kg)

Weight at axles (estimated): 41,500 lb (18,824 kg)

Length (conveyor folded): 45.1` (13.7 m)

Length (conveyor unfolded): 66.7` (20.3 m)

Width: 8.5` (2.6 m)

Height (transport): 13.5` (4.1 m)

Height (operation): 18.5` (5.6 m)

Tongue weight: 21,000 lb (9,525 kg)

Cab

Heat and air conditioning filtered and pressurized

Windows side, rear and front: .38" (.97 cm) LEXAN

Front intrusion guard

AM/FM stereo with MP3 capability

Pilot operated seat mounted joystick controls

Front window wiper/washer

Loader

Pedestal/cab rotation: 370°

Reach: 27` (8 m)

Lifting capacity 10’ radius: 12,250 lb (5,557 kg) Full reach: 3,500 lb (1,588 kg)

Grapple rotation: Continuous 360°

Grapple types: High-capacity multi-tine or bypass

Grapple weight (high-capacity multi-tine): 1,065 lb (483 kg)

Grapple weight (bypass): 810 lb (367 kg)

Operating height (approximate seated operator’s eye level): 17.5` (5.3 m)

Pump: Load sense, PSI comp

Stabilizers: Rear hydraulic

Options

Extended warranty

Special paint

Magnetic pulley