Cryo Systems Refrigeration Equipment Co., Ltd.

- Home

- Companies

- Cryo Systems Refrigeration Equipment ...

- Products

- Cryo - Tunnel Freezer

Cryo - Tunnel Freezer

IQF is an abbreviation for “individually quick frozen”, a process that freezes food rapidly so there is minimal damage to the cellular structure of the food. A tunnel freezer is a class of processing freezer systems where the product usually travels horizontally through a long enclosed space (freezing tunnel) and cold air is circulated upward through the product.

Most popular related searches

- The S Belt

- Low noise S Fan

- High-quality Runner

- SS Fan

- Belt Tension Device

- High-Quality Evaporator

- Advanced Deflection Proof

- High-density insulation panel

- Safe and reliable equipment configuration

- Multiple energy-saving designs

- High-quality evaporator

- Top quality insulated panel

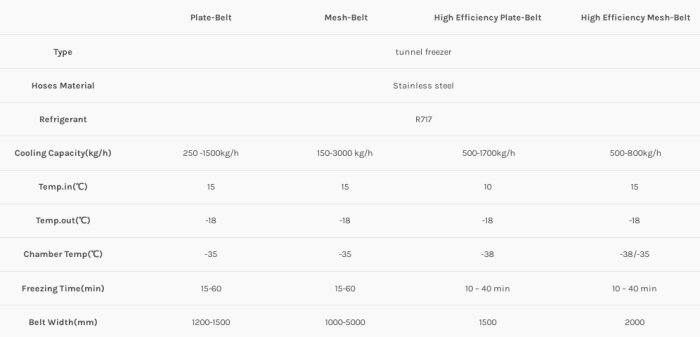

1. Plate-belt tunnel freezers Features

- Imported strong Intensity stainless steel plate

- High stick-on plastic strips imported from Japan keep the belt normal running.

- Belt running inside to avoid outside pollution and cold loss

2. Mesh-belt tunnel freezer Features

- Special patent driving ensures belt smooth running.

- No distortion while loading based on high-quality SS spring for the belt.

- Vide belt design for wide product scope, strong bearing capacity.

- Keep the belt correct running by air pump while occurs deflective running.

3. High-efficiency plate/mesh-belt tunnel freezer Features

- Quick freezing, 200g/ fillet passing time is 17 minutes.

- With Lower moisture-lost.

- The Optimize airflow system design, add nozzles on both sides of the belt to improve heat exchange efficiency.

- The Two belts are installed in the same freezer where has a partition to save room.

- Parts inside without any oil and outside driving devices keep oil pollution from product processing.