- Home

- Companies

- Turbotec Engineering

- Products

- Turbotec - Dredging Pump

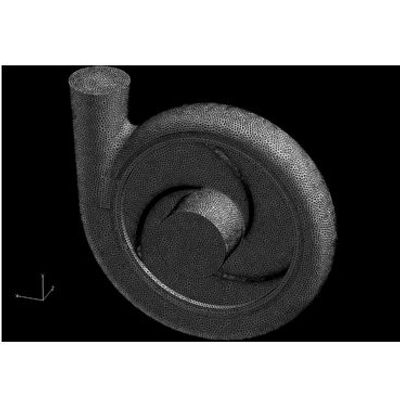

Turbotec - Dredging Pump

Dredging pumps are used in challenging environments and suffer greatly from wear in the volute and occasional blockage in the impeller channels. This leads to early replacement and frequent operational downtime. Large dredging pumps such as these cost well over 100.000€ each, but for these highly expensive dredging ships, the real cost is the operational downtime.

The excessive wear and the possible blockage of the impeller channels makes the design a challenging task as performance is no longer the single most important objective. Wear can largely be reduced by ensuring a smooth flow from the entry through the impeller channels into the volute and by minimising the number of low energy vortices.

A Flemish manufacturer of large dredging pumps was interested in improving the wear characteristics of their current design. The task of simulating the flow inside the pump using CFD, in order to locate and assess the stability of these vortices and corresponding high shear zones in the volute and the impeller, was awarded to TURBOTEC.