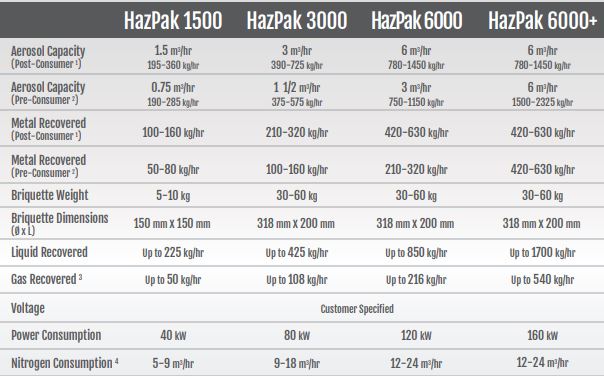

MacLean HazPak - Model 1500, 3000, 6000 & 6000+ -Turn-key System

The engineering design team at MacLean Engineering spent several years developing the idea of a zero-waste solution for aerosol and high-pressure propellant containers. The technology needed to have the capacity to recycle bulk amounts of cans efficiently, while keeping the MacLean standards of safety and quality. We are proud to announce we have achieved this goal through our HazPak system.

HazPak captures liquids and gases in their entirety, preparing them for waste-to-energy applications in a near zero emissions environment. Steel and aluminum bricks are ejected from the machine as non-hazardous materials and are accepted at scrap metal businesses around the world.

With eight installations in operation, each HazPak is tailored to our customer’s unique, site-specific requirements, resulting in no two machines being the same. Whether you have strict environmental regulations, limited facility space or unique recycling volumes, our team will make sure each condition is met.

SAFETY

- Nitrogen is inserted throughout the entire recycling process to eliminate risk of explosion

- Diagnostic reports are sent to MacLean engineering team through secure internet connection

- Operator can easily monitor equipment processes using the touch screen controls on the 19-inch LCD display

PERFORMANCE

- Eight working installations around the world (Canada, US, UK, Germany)

- Highest available throughput on the market of 6000 cans/hour

- Smaller models are available for customers with lower aerosol recycling volumes, or for customers who prefer installations at multiple facilities

- Able to process aerosol cans, paint cans, small propane cylinders, and medical inhalers

OPERATION

- Single employee operation for smaller models, two employees’ for larger models

- No operator fatigue - Operator loads cans into machine, touches start button from the display, and collects ejected cans from the machine every hour

- Each machine is custom designed to fit within the space available at customers’ facility

REVENUE STREAMS

- Owners’ can charge disposal fees for collection and treatment of aerosol cans

- Metal bricks can be salvaged for scrap metal

- Recovered gas has high BTU value

- Recovered liquid provides fuel source for incineration or cement kilns

Knowing how to safely and efficiently dispose of empty aerosol cans remains our forte. It is very important to educate ourselves about proper ways of disposing aerosol cans since it makes for an important part of our environment sustainability efforts. Disposing them indiscriminately to empty landfills is harmful for the environment as they contain propellants which are susceptible to explosion when exposed to heat. Proper Aerosol can disposal requires you to take them to certified Recycling facilities or can crushers.

Aerosol cans, hand-held propane torches, shaving cream, hair spray and multitude of products packaged under pressure are flooding our landfills. They contain hazardous materials, they are explosive and they have to be dispiosed of safely, economically and without harming the environment. Dumping these full and partially full containers into land fills is at best delaying the contamination is not the answer. The HazPak by MacLean Engineering is the answer.

This state of the art de-packaging “densifier” can separate and remove both the propellant and the liquid and save them in separator containment tanks for recycling or incineration. The metal containers are compacted into a dense dry briquette with 99 per cent of the liquid removed, which makes ideal feed stock for smelters. The entire operation occurs inside the safety of an air tight vacuum. The system is fully automated.

The operator loads a drum of aerosol cans onto the loading platform and presses the start button. The HazPak hopper is automatically purged with inert nitrogen gas creating a non-explosive atmosphere should a spark occur when the drum is lifted into place and the cans are gravity fed into the hopper. The lid is automatically closed and sealed. The nitrogen and any residual air inside the hopper are pumped out and the containment eld sensor checks to ensure a proper vacuum has been created.

The compaction cycle then begins. The stage one ram crushes the cans using 4500 P.S.I. releasing most of the liquid and the propellant gas. The propellant is drawn o and re-compressed into a holding tank for recycling or incineration. The liquid goes to the bottom and is pumped into an adjacent holding tank for recycling. The stage two ram then compacts the crushed cans using 15,000 p.s.i. of pressure into a dense briquette with 98 percent of the liquid removed. The briquette is then pushed into an air lock and the densi cation cycle begins again until all the cans in the hopper have been processed. The hopper is purged with nitrogen gas and is ready to receive another load of cans.

Throughout the process the operator can visually monitor the operation in real time and modify the operation using the touch screen controls on the LCD display. Safety and performance are key factors in the HazPak system. The HazPak is intrinsically safe through mechanical interlocks to prevent any escape of the propellant or liquid into the atmosphere. Safety sensors speci cally designed to work in explosive atmospheres are located at strategic positions inside the HazPak and provide continuous monitoring information. It allows the operator to intervene, to move the stages, to open or close the gate and to obtain diagnostic information.

Paint can recycling and paint can disposal can be a problematic process due to the fact that aerosol cans are mostly regarded as hazardous waste in many countries. There are valid reasons behind categorizing used aerosol cans as hazardous wastes. These spray cans contain highly combustible propellants in addition to the main products. When these propellants come in contact with heat, they can lead to an explosion. So, if they are disposed of arbitrarily in empty landfills then there is every chance of these cans exploding when they come in contact with sunlight—thereby hurting the landfill worker.

WHAT YOU SHOULD FIND OUT ABOUT SPRAY CAN DISPOSAL?

So, it is actually very important to ensure that users of spray cans are acquainting themselves with the proper ways of Spray can disposal so as to ensure that you are not unwittingly contributing to the entire imbroglio. Today, we will be discussing a few aspects of proper spray can disposal, so that you can actually go on to make an informed decision the next time you are using them.

The countries which treat aerosol cans as hazardous wastes generally require you to submit the cans to a hazardous waste facility until and unless they (i.e. these cans) are totally empty. However, one must educate himself about the “emptiness” of the can in this regard. A can is only considered empty when you have actually taken the trouble to drain out the propellant besides the main product as well. The propellant is the combustible agent responsible for forcing the product out of the can. You need to ensure that you are draining the propellant out of the can (along with the main product like spray paint) if you are willing to take this can to a nearby recycling facility. Needless to say, if you are not draining the propellant out of the can, then you should seek the help of the local hazardous waste facility in order to get rid of the cans. Read on to find out more.

CAN YOU DRAIN OUT THE PROPELLANTS ON YOUR OWN?

Even you can drain out both the propellant and product from the cans by thoroughly spraying them. Make sure you are performing this operation in a well ventilated area for safety reasons. You will need a few papers on which the contents would be sprayed. Keep on spraying until the hissing sound stops. If you are not sure whether the can is empty or not then make sure you are taking the container to a licensed puncturer. Do not try to flatten or crush or puncture the can on your own. The remnants of the propellants might as well end up hurting you as well.