Crown Machine UWP, Inc.

Crown - Twin Screw Extruders

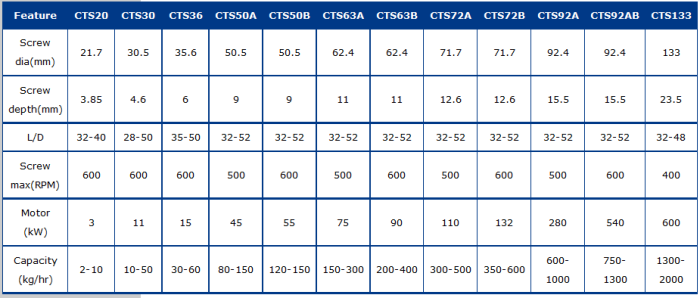

Ideal for production of polymers to enhance physical, electrical, mechanical, optical and chemical properties. Used for various processes such as compounding, pelletizing, pipe production and coating, profile and sheet extrusion, wire coating and blown film. Available in 30mm, 40mm, 50mm, 60mm, 70mm, 80-83mm, 90-92mm, 120-133mm, 160-177mm and 240-260mm diameters with variety of standard and custom-designed screws and barrels are available for various applications. Can be assembled in any combination to provide plasticizing of raw material feeding, ventilation or gas extraction

Most popular related searches

twin screw extruder

screw extruder

screw feeder

pipe coating

atmospheric pollution

contaminants removal

pelletizer

pelletizing

pipe profiling

- Raw material is meter fed into the extruder throat

- Material is heated and advanced along the barrel by two co-rotating intermeshed screws that mix the material as it travels down the barrel

- Raw material melts and becomes molten material that passes through a scheen changer to remove contaminants

- Atmospheric and/or vacuum venting can be engineered into the process

- Custom designed barrels and screw configurations

- Flexible, modular design

- Self-cleaning screws due to co-rotating, intermeshing, parallel arrangement

- Screw elements finish include stainless steel, Dura-Nickel, nitride hardening, CPM10V, chrome or plasma coating

- Easy access venting system reduces cleaning and maintenance time

- Greater temperature specificity due to divided heating and cooling zones in the barrel

- Capable of processing all thermoplastics, non-thermoplastics and rubber materials

- Twin screw side feeders with variable speed AC Drive are available for force feeding mineral fillers into the sie of the extruder