- Home

- Companies

- Enerpat Group

- Products

- ENERPAT - Model MSB-E Series - Two ...

ENERPAT - Model MSB-E Series -Two Shaft Shredder

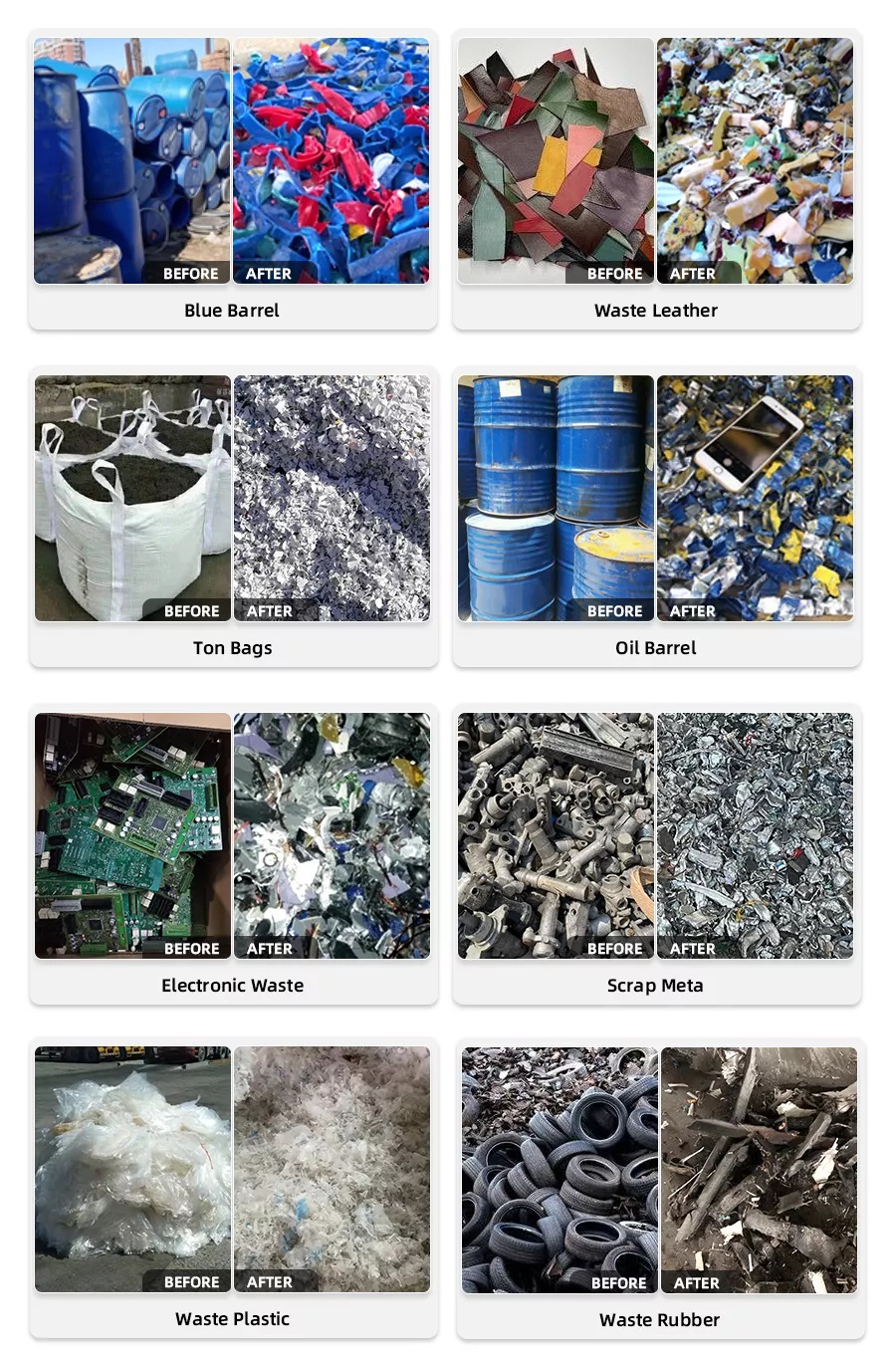

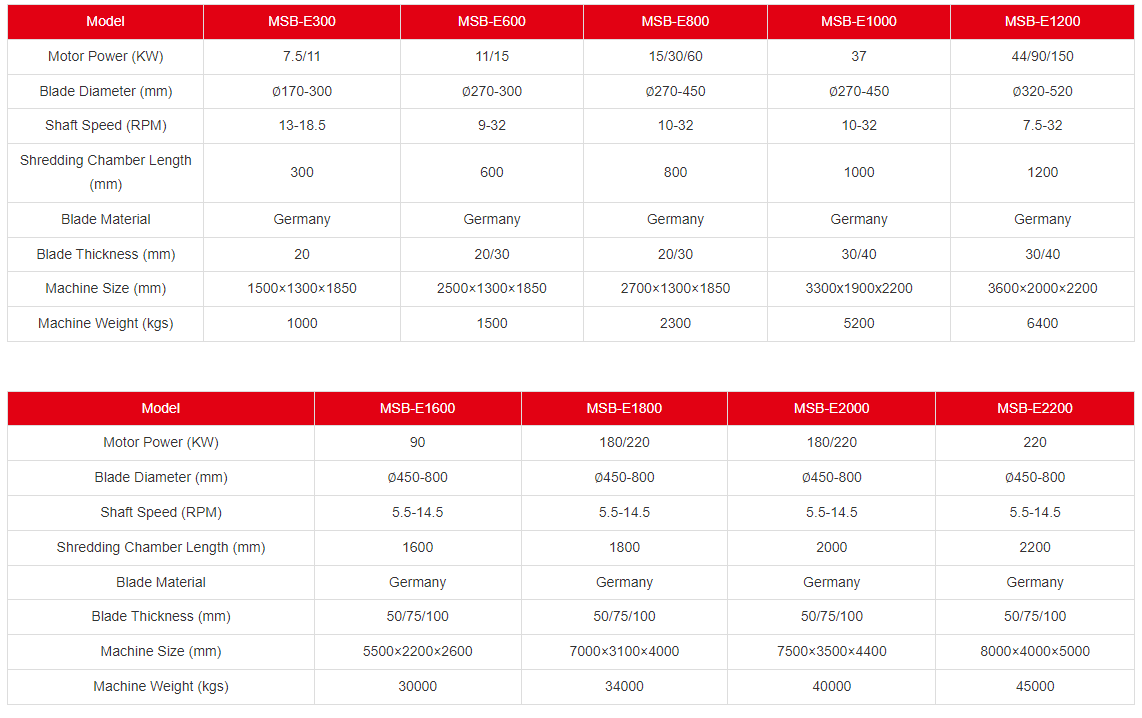

MSB-E Series Two Shafts Shredders are small to large size reduction machines suitable for processing a wide range of materials to a smaller size. The products can often be sold as is, or be sent for further processing through additional equipment. Throughout typically range between 300kg/hr – 20,000kg/hr+ depending on the model, material type and application. MSB-E Series Two Shafts Shredders are widely used in the volumetric reduction of various waste products, including but not restricted to the following. Light Scrap Metals,Bulky Waste,Wood Waste,Plastic Waste,Cardboard waste,Textiles Waste,Domestic Rubbish & Electronic Waste. The Output material discharged by the shredder could be an end product or the primary feed for the next process.

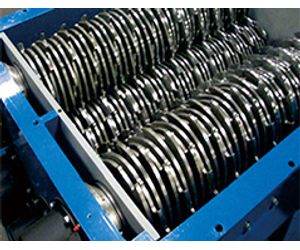

The shredding chamber body can be deconstructed from each end of the coupling. The main shaft can be detached as a whole by removing the mounting plate at each end of the bearing.

Once the main shaft is dismantled,the cutter body and bearings can be kept and inspected,and if need be,then it can be replaced as well.

Regarding the processing ofthe shredding chamber,care should be taken to position the main shaft and bearing at central position during installation to ensure that the structure remains intact and lasts longer.

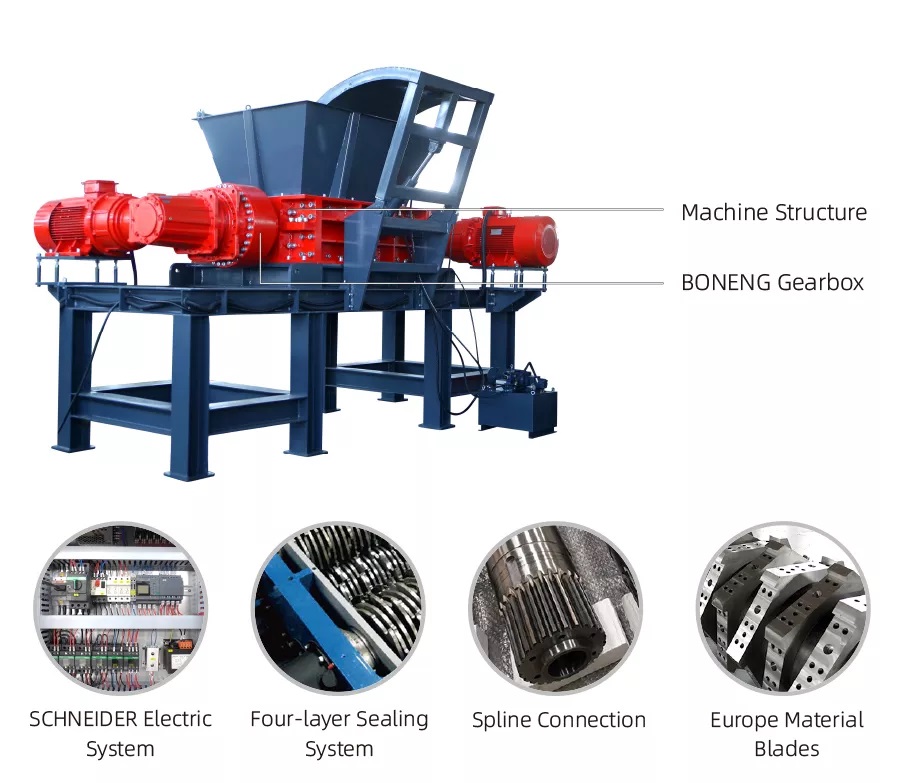

It has a box of rigid casting reducer consisting of gussets.

The sturdy finishing gear is composed of high-quality steel alloy,and the surface is processed through carburizing and quenching methods.

Then,the structure is finely processed by means of gear grinding.This through process ensures many operational benefits,such as stable transmission power, low noise and greater carrying capacity.

Detachable blade design greatly reduces blade replacement time

A complete crushing blade comprises of three parts.

It is quite easy to replace a worn blade: simply loosen and tighten the bolt.

The electric cabinet is equipped with a Siemens/Schneider PLC.

The electric cabinet boasts a touch screen with a high capability of promoting human-machine interaction.

Siemens/Schneider electrical components are adopted.

The bearing has a quadruple sealing protection design which makes it dust proof and waterproof, effectively prolonging the service life of the bearing.

Therefore,it can work excellently in an outdoor, highly dusty environment.

A pressing device is optional.It can help to crush materials rapidly.

A rotating screen is optional,and it guarantees dimensional uniformity of crushed products.

The moving blade base and the main shaft align in spline transmission.

The design consist of a large surface junction without stress concentration.The spiral configuration of the moving blade base can enhance its crushing efficiency and reduce energy consumption.

The moving blade base has been tested by using 100% ultrasonic and non-destructive inspection to maximize the cutter`s crushing capacity. dimensional uniformity of crushed products.

We install heavy-load self-aligning bearings on two main shafts.

When a blade is impacted by a heavy load,the heavy-load self-aligning bearing produces an immense mechanical action that relieves the impact force.

We choose the world`s leading bearings.of brands such as FAG and SKF as a standard configuration for all ENERPAT shredders.

Conveying to Feed-In

Conveying to shredding chamber by forklift or conveyor

Utilizing the principle of mutual shearing and tearing between two rotating blades to shred the material.

The material is shredded into strips or pieces, realizing the rough shredding effect of the material.

The shredding machines can also be equipped with additional separating and conveyor technology, customized hoppers and substructures and control expansions. We offer comprehensive solutions from one source!