- Home

- Companies

- Energy Recovery, Inc.

- Products

- Energy Recovery - Model PX - Ultra ...

Energy Recovery - Model PX -Ultra high-Pressure System

The key to lower energy use in wastewater treatment and reuse for ultra high-pressure applications, helping make zero and minimal liquid discharge (ZLD and MLD) low-cost and energy-efficient.

Maximizing energy savings in ultra high-pressure applications

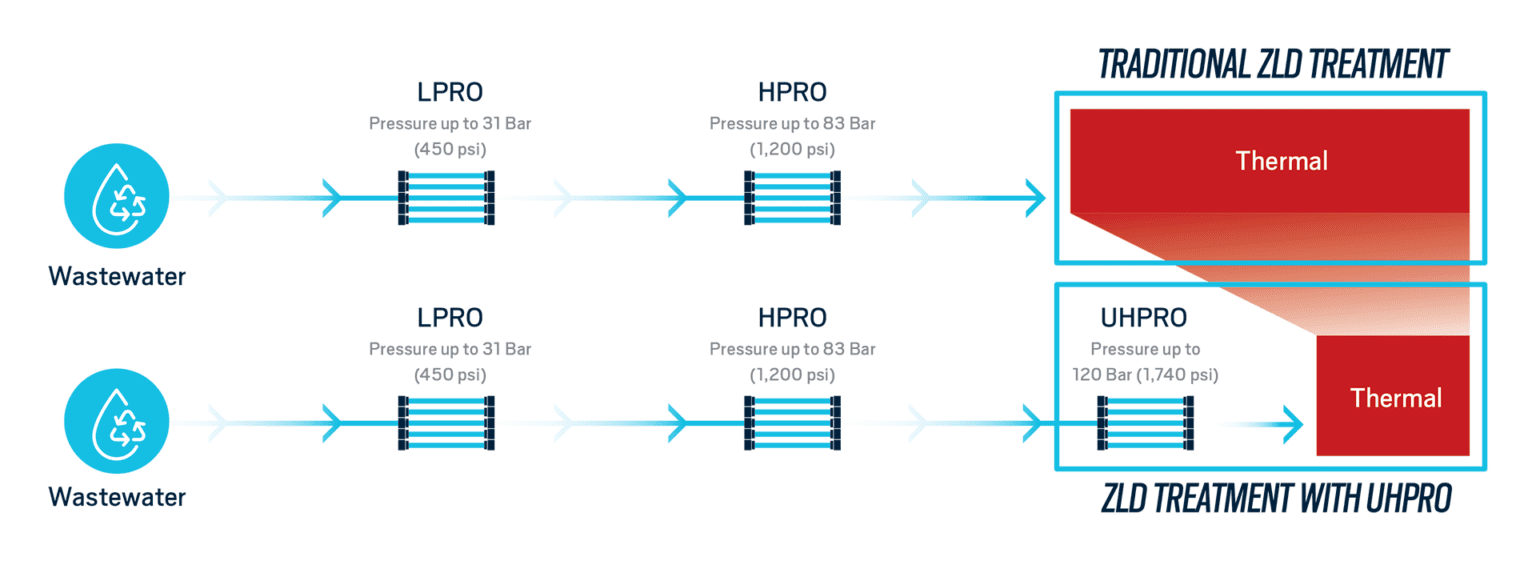

Sustainable treatment of industrial wastewater can help drive a circular water economy, reduce emissions, and recover valuable resources from wastewater. By using our cutting-edge U Series devices to increase the efficiency of ultra high-pressure reverse osmosis (UHPRO), implementing minimal and zero liquid discharge can become less costly and reduce harmful discharge into the surrounding environment. The PX U Series is tailored for UHPRO applications, can handle higher brine concentrations, and operates at pressures of up to 120 bar (1,740 psi). Its modular design makes it ideal for small or large wastewater treatment plants.

- 65% Potential recovery, in all flow conditions, of otherwise wasted energy

- 30 Years Designed to last with no scheduled maintenance

- 97% Peak efficiency of U Series

- 1740 PSI Maximum operating pressure of U Series

Typically, in plants using ZLD or MLD for wastewater treatment, 50% of the cost is driven by the last 10% of the process due to the use of high-cost treatment technologies such as mechanical vapor compression (MVC), forward osmosis (FO), and electrodialysis (ED). UHPRO moves the cost of those technologies further downstream. The PX U Series further reduces the energy waste of the UHPRO process by returning pressure energy to the system, ultimately reducing overall energy costs.

Industry-leading efficiency in all flow conditions

No scheduled maintenance required due to one moving component and a corrosion-resistant alumina core

Compact, modular and scalable with low operational expenditure and fast payback

Lower the energy consumption of wastewater treatment for reduced greenhouse gas emissions