Fote - Model HGM -Ultrafine Grinding Mill

Ultrafine grinding mill is a kind of Raymond mill. It is widely used in the grinding process of ore materials in metallurgy, building materials, chemicals, mining minerals areas such as various non-flammable materials of quartz, feldspar, clay, kaolin, bentonite, calcite, talc, barite, fluorite, clay, white clay, gypsum which Mohs hardness is below seven degree and humidity below 6%.

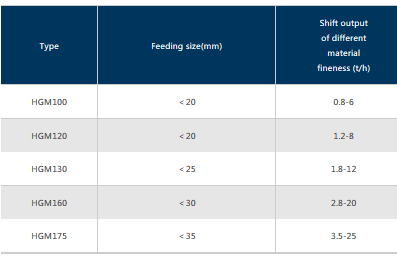

- Processing ability: 0.2–21 t

- Feeding size: ≤25 mm

Product granularity : 0.125–0.010 mm

- Low investment cost; under the same fineness condition, it has lower input than air current mill; lower cost and shorter recovery period.

- Under the same fineness of finished products and power, its output is higher by 45% than air current mill and stirred mill.

- The quick-wear part has low consumption. All the quick-wear parts adopt good quality wear-resistant material from home and abroad and have a longer life than those of common grinding mill which can last more than one year.

- The operation is safe and reliable in the grinding chamber. Compared with the ordinary grinding mill, the grinding cavity has no rolling, no screws, so the bearings and other seals are not easy to be damaged to avoid the problems of loosening the screw.

- The fineness of finished product is high, and one time ultimately fineness can reach d97 ≤ 5μm.

The main engine of ultrafine grinding mill device has integrated the crushing, classifying with the plenum. The materials are crushed in the crushing chamber and strictly controlled by the grading room. The fineness of materials beyond the standard cannot get through the grading room and be crushed in the crushing chamber until reach to the standard, then they enter into the compartment from grading room. The winds bring the materials into a whirlwind powder set, and then they are discharged by dust filtering bag. The whole operation process is without dust.