- Home

- Companies

- Unicon Engineers

- Products

- Unicon - Clam Shell Gate / Sector Gate ...

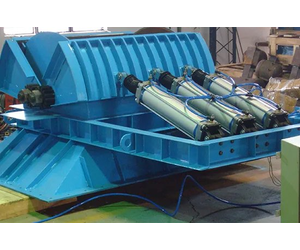

Unicon - Clam Shell Gate / Sector Gate Systems

UNICON’s Clam Shell Gate / Sector Gate Systems facilitate efficient unloading of dust and coarse particles from hoppers and storage bins, optimizing industrial operations.

Cost-Effective Clam Shell Gate Systems

Unicon`s Clam Shell Gate Systems offer a cost-effective solution with simple, common components.

- Lower Initial Cost

- Simplicity

- Low Operating Speed

- Reliability

- Durability

- Versatility

Why Choose UNICON

At UNICON, our specialization lies in delivering dependable Clam Shell Gate / Sector Gate Systems engineered for efficient bulk material unloading. With a commitment to excellence, we offer:

- Cost-Effectiveness

- Industry Expertise

- Innovative Design

- Global Reach

- Customer Satisfaction

- Custom Solutions

UNICON has been manufacturing clamshell gates for bulk material handling systems for more than decade. Our clam shell gates can be used any type of bulk material handling whether it is high temperature, adhesive or abrasive. We are providing Hardox 400, Hardox 200 or Hardox 500 lining for all material contact surfaces according to the application. Our state-of-the-art clam shell and testing facilities is the key of achieving optimal performance.

Parameter : Data

- Application: Cement, Clinker, Gypsum, Fly Ash, Sinter dust, Sponge Iron, Coal Dust, Etc,.

- Capacity: 1 TPH to 300 TPH

- Temperature (°C): 350° C Max

- Opening Size: Upto 2000 mm

- Flange Type : Square or Rectangle

- Material of construction: Mild Steel

- Construction method: Fabricated

- Abrasion resistant lining: Sail Hard, Hardox or Stainless Steel as per requirement

- Drive type: Motorized / Pneumatic / Hydraulic

UNICON`s Gear Gate Systems are engineered for durability and reliability in material handling operations. Constructed from minimum 6mm mild steel plate and reinforced as needed, these systems feature welded gear sets for precise timing and minimal maintenance. Actuated through PLC systems, they ensure smooth material flow without the need for lubrication, offering robust performance per AWS standards.

- Low Stresses Seen By the Gear Teeth during Operation.

- Lubrication Of The Teeth Is Not Required.

- Once the gear sets are located and properly timed, they are welded in place eliminating any further adjustment or need for maintenance.

- The assembly and reassembly of the gate can be accomplished without affecting timing of the gate blades.

- The gate actuation through a PLC system to control the desired opening to facilitate smooth flow of material.

- Construction is of minimum 6mm mild steel plate, heavily reinforced where necessary. Bolting flange is constructed of heavy structural steel angle. All welding is per AWS standards. Gate pivot shafts are C-1045 steel shafting, and are attached to heavy backing plates welded to the gate body.