- Home

- Companies

- Unicon Engineers

- Products

- Unicon - Double Cone Valve

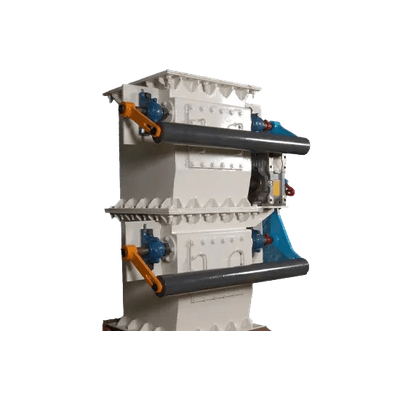

Unicon - Double Cone Valve

Double Cone Valves hold a prominent position in the market due to their exceptional ability to provide controlled feeding and maintain airtight sealing between the collection chamber and conveying equipment.

Reliable Double Cone Valves

Unicon`s Double Cone Valves are built to excel in high-pressure applications, offering superior performance with minimal maintenance.

- High Pressure Capability

- Efficient Performance

- Durability

- Minimal Maintenance

- Versatile Applications

- Enhanced Safety

Why Choose UNICON

At UNICON, we are dedicated to providing top-quality Double Cone Valves that meet the highest standards of performance and reliability. Here’s why you should choose us:

- Expertise

- Quality

- Customization

- Innovation

- Global Reach

- Customer Support

Description : Data

- Application: Cement, Clinker, Gypsum, Fly Ash, Sinter dust, Sponge Iron, Coal Dust, Etc,.

- Capacity: 1 TPH to 100 TPH

- Temperature: 350° C Max

- Opening Size: Upto 500 mm cone

- Flange Type : Square or Rectangle

- Material of construction (Casing): Mild Steel / Stainless Steel

- Material of construction (Cone): Ni Hard / Cast Steel / Cast Iron as per requirement

- Construction: Fabricated

- Abrasion resistant lining: Sail Hard, Hardox or Stainless Steel as per requirement

- Drive type: Geared Motor through cam

Unicon Products are distributed worldwide. Besides a extensive range of standard components, we supply international standards sanitary versions and explosions proof models. We have been designing and manufacturing Double Cone Valves for bulk solid industry for more than 30 years. Offering tailor made solutions for cement, coal, power plant, Paper, Sugar, Chemical, Steel, etc.,

Our Double cone valves are designed specifically for long life in handling. The wide selection of available actuators and control component allow easy integration with any degree of automation. A choice of mild steel Hardox 400, Hardox 500 & stainless steel materials gives the option of selection material of construction to suit your particular needs.

- Robust design for continual operation.

- Sizes can be supplied according to client requirement.

- Actuation will be manual, motorized, pneumatic.

- Rectangular and Square inlet and outlets are available.

- 100% sealing at high temperature can be provided for special requirements.