- Home

- Companies

- Universal HDD

- Products

- Universal - Model HARR - Culvert ...

Universal - Model HARR -Culvert Cleaner

Harr Technologies, owned and founded by Bob Harr, has developed a revolutionary method for cleaning and restoring clogged and damaged culverts. It all started a few years ago when Bob Harr noticed county workers open cutting a road to remove a clogged culvert. After further observation around his hometown in Colorado, Bob Harr noticed road washouts and failures due to clogged and damaged culverts.

After seeing a need for an efficient and effective way to clean these clogged culverts, Harr spent much time researching and developing culvert cleaning attachments for his horizontal directional drill(HDD). After much testing and tool modification, Harr had developed a set of tools and a revolutionary methodology to effectively clean clogged culverts.

During the past few years, Harr and licensed contractors have marketed and demonstrated this process to railroads, DOTs, counties, municipalities and other entities and have developed a new industry for culvert cleaning using HDD technology. To expand this industry, Harr has licensed contractors throughout the United States to use his patented tooling and methodologies. Licensees have exclusive rights to use the culvert cleaning process withing their assigned districts.

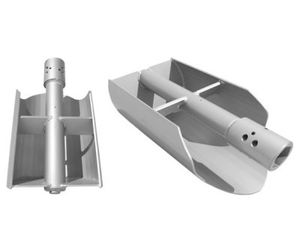

Box Pull Bucket

Box configuration is specifically designed for box culverts made of single or multiple cells. The box pull bucket comes with two extensions to accommodate for different culvert sizes. Featuring a simple, yet reliable locking mechanism, extensions can be easily connected and disconnected within minutes. The operator drills a pilot hole through a clogged culvert, connects a pull bucket to the drill pipe on the other end, and pulls back unwanted debris.

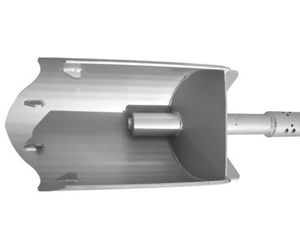

Pull Bucket

The round pull bucket is designed for round culverts. It comes in several sizes to accommodate for different diameter culvers. It works in a similar manner as the box pull bucket. An operator drills a pilot hole through a clogged culvert, connects a pull bucket to the drill pipe on the other end, and pulls back unwanted debris.

Push Bucket

Push bucker specifically designed to push material out the far end of the culvert. It comes in several sizes to accommodate for different diameter culvers. Unlike pull bucket, a push bucket is connected to the drill stem at the beginning and it is pushed down a culvert, consequently forcing debris and material out of a culvert. It can also function as a scoop removing material bucket full at a time.

Barrel Reamer

Barrel reamer is designed to loosen and remove heavy material located in the culvert. By utilizing rotational force and push force of horizontal directional drill, a barrel reamer is pushed trough a culvert while rotating. This allows to loosen compressed debris and forces it out of a culvert. It comes in several sizes to accommodate for different diameter culvers.

Brush

Brush tool is designed to fine clean a culvert. Designed and constructed with heavy-duty materials, this brush can withstand extensive abrasions. Featuring a large industrial metal brush that is very effective at cleaning clay, sand, gravel, as well as removing debris. It comes in several sizes to accommodate for different diameter culvers.

With the awareness of environmental hazards detailed by federal and local regulations, it is important that drainage structures are properly maintained. In the past these structures have not been given the attention they deserve. Many culverts in the U.S. have never been cleaned which has resulted in damages to the structures themselves, roads, ditches, personal property and even people. One of the main reasons organizations have not maintained their structures is due to the lack of efficient and effective culvert cleaning methods. Open cutting a road, jetter trucks, backhoes and cables are all methods that have been used to clean culverts in the past. Each of these methods have their shortcomings.

Efficiency

During HARR`s development, he did a head-to-head competition with his process and a jetter truck. He found a culvert with 2 pipes. He cleaned the first pipe with the jet truck and completed the cleaning in 6.5 hours and used 1200 gallons of water. The second pipe he cleaned with his method and was done in 40 minutes and used 110 gallons of water.

Versatile

Using a directional drill culverts of any size, shape and material can be cleaned effectively.

Reduced Water Usage

When using a jetter truck, potentially thousands of gallons of water can be used to effectively clean a culvert. HARR`s method will use a fraction of that. For example, a 60` culvert with a diameter of 24" that is 100% full can be cleaned using between 100-250 gallons of water. Using HARR`s method the water usage and pressure are controlled by the drill operator. The water is pumped through the drill stem to the culvert cleaning attachments.

Structurally Safe

The culvert cleaning tools are built out of a mild steel that will not damage the interior of the culvert. Using a directional drill allows the operator to control the rotation of the tools. This is very important especially when a failure or void is encountered. With total control the operator will be able to back out the tool to determine where the failure is.

Containment of Debris

Using a directional drill gives the operator complete control of the debris within a culvert. With controlled pullback and thrust speeds the operator can remove as little or as much material as they want at a controlled speed. This will allow for the material to be shovelled, excavated or vacuumed as it is being removed from the culvert. Using a pull bucket or push bucket, material can be removed from either end of a culvert.