- Home

- Companies

- Sterling Deaerator Company

- Products

- Sterling - Unparalleled Sterling Spray ...

Sterling - Unparalleled Sterling Spray Valve for Maximum Dissolved Gas Removal

Sterling`s deaerators utilize the unparalleled Sterling spray valve for maximum dissolved gas removal. The Sterling spray valve is cast from rugged, non-corrosive type 316L stainless steel to ensure maximum life. This self adjusting, non-guided spray valve can handle flow up to twice its rated capacity, while maintaining an effective, consistent spray pattern. Because the Sterling Spray Valve is hydraulically balanced and non-guided, solid particles and debris pass harmlessly through the valve without clogging or reducing performance. As described in the deaerating principle, the thin film of feedwater sprayed into the steam atmosphere provides rapid heat transfer and gas removal. The Sterling spray valve produces that essential thin cone of feedwater consistently over its operating range, resulting in continuous deaerating performance.

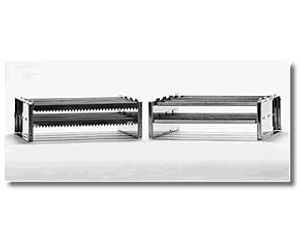

In addition to Sterling`s superior spray valve, our tray type deaerators are also equipped with the Sterling tray assembly. The Sterling tray assembly is constructed of 16 gauge, type 430 stainless steel, and is fastened with stainless steel rivets. Each tray assembly consists of two staggered rows of four tray channels. This staggered tray channel pattern ensures maximum feedwater retention and reduced pressure drop which results in optimum heating surface and deaeration. The Sterling tray assembly, as well as the Sterling spray valve, is designed to be resilient: able to withstand upset and extreme conditions resulting in reduced downtime. Rugged construction combined with lower steam pressure drop extends deaerator life even under the most severe operating conditions.