- Home

- Companies

- Untha Shredding Technology Gmbh

- Products

- Untha - Turnkey Industrial Shredder

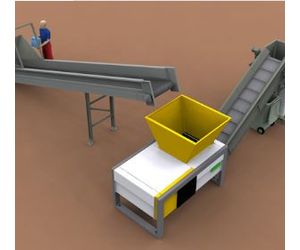

Untha - Turnkey Industrial Shredder

We only use respected, long-standing industry partners to ensure different equipment integrates together perfectly. Entrust your brief to UNTHA for a sole point of trusted contact, engineering simplicity, enhanced on-site safety, cost savings, ongoing support and more. Adopting the highest project management standards from day one, our ISO- and NEBOSH-accredited engineers deliver a range of UNTHA service products to maximise shredder efficiency long into the future. Turn a `blank canvas` into the perfect recycling, waste management or alternative fuel production line. When involved from the outset, our knowledgeable consultants get to the heart of the equipment you really need to design a seamless end-to-end solution.

We have worked in virtually every segment of the waste and recycling world including:

- Alternative fuel production/ Waste to Energy

- Confidential waste

- Secure product destruction

- WEEE

- Metals

- Plastic, packaging and production waste

- Pallets, wood and timber waste

- Organic waste

Plant design

Some clients approach us at the earliest conceptual phase of their project, to maximise a site`s footprint, capacity, efficiency and yield.

Shredders

For half a century we`ve specialised in the manufacture of robust industrial shredders for an array of waste, recycling and alternative fuel applications.

Conveyors

We know which infeed and outfeed equipment is required for the successful handling of materials, at different stages in the waste/recycling process.

Ancillary equipment

Some solutions are extremely simplistic in design, but others require an array of magnets, generators, eddy current separators and control rooms. We can advise depending on your needs.

Project management

We`ve invested heavily in technology-driven, ISO-accredited processes that enable our highly-trained team to bring

projects in on time, and to budget, with minimum client fuss.

Engineering and commissioning support

Our world-class engineers are trained at UNTHA`s own academy just outside Salzburg, and their development remains ongoing to ensure we commission every installation safely, swiftly and with client ROI in mind.

Associated spare and wear parts

Your shredding system can be made up of hundreds of component parts. With a fully stocked UK warehouse, our aim is to support customers long after the initial installation, for maximum uptime and yield.

Ongoing service and maintenance expertise

From remote diagnostics when the solution needs some TLC, to operator training, the creation of preventative maintenance plans and routine service inspections inclusive of machinery optimisation advice, our goal is to be your long-term partner.

Plant finance

Some clients will always want to purchase their solution outright whereas others will prefer to spread the cost over a term to suit them, with the option to include parts and servicing within the affordable monthly fee .