UQG Optics Ltd.

- Home

- Companies

- UQG Optics Ltd.

- Products

- UQG Optics - Alkaline-Free Glass Plates ...

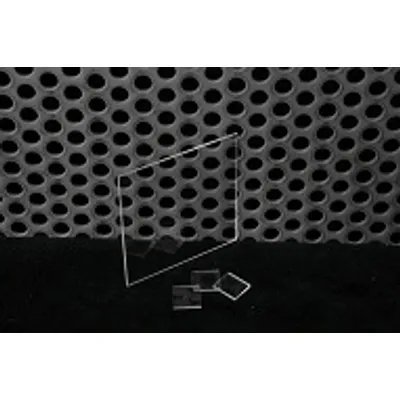

UQG Optics - Alkaline-Free Glass Plates for Optoelectronics and Microscopy

FromUQG Optics Ltd.

Alkaline-free glass plates provided by UQG Optics include a variety of boro-aluminosilicate, modified borosilicate, and alumina-borosilicate thin glasses. These glasses are notable for their low thermal expansion and high light transmission within the visible wavelength range, extending significantly into the infrared (IR) spectrum. Thinner glass variants are also capable of ultraviolet B (UVB) transmission. The glass surfaces are characterized by their smoothness, excellent surface quality, and flatness, featuring low microroughness of less than 1 nm (RMS). These plates are primarily used in optoelectronics, optical sensors, MEMS (Micro-Electro-Mechanical Systems), and microscopy applications, including microscope slides and cover slips. UQG offers these glasses as standard stock or customizable substrate formats, including specific diameters and squares, tailored to customer requirements. For volume pricing, discounts are available for orders of ten pieces or more.Most popular related searches

borosilicate glass

microscope slide

optical sensor

optoelectronic

microscopy

aluminosilicate glass

optoelectronic sensor

surface characterization

microscopy system

microsensor

Alkaline free glasses can cover a range of boro-aluminosilicate glasses, modified borosilicate glasses and alumina-borosilicate thin glasses. The glass has low thermal expansion and high light transmission for the visible wave length and can transmit far into the infrared (IR). The thinner glasses also transmit down into UVB range. The surfaces are very smooth and excellent surface quality and flatness with a low micro roughness <1 nm (RMS). Typically used in optoelectronics, optical sensors, MEMS (Micro-Electro-Mechanical Systems) and microscopy for microscope slides and cover-slips.

UQG optics alkaline-free glasses are made as substrates, diameters and squares to a standard stock range or custom made to your design.

- Material: Schott AF45® & AF32® eco - Alkali Free Glass Borosilicate

- Dimension Tolerance: ± 0.10mm

- Thickness Tolerance: ± 0.10mm

- Edge Finish: Fine ground

- Surface Quality: 60/40 Scratch/Dig

- Surface Flatness: ≤ 5 Fringes (@633nm) per 25mm dia