- Home

- Companies

- ANDRITZ Separation - ANDRITZ Group

- Products

- Andritz - Model CORES - Vacuum Drum ...

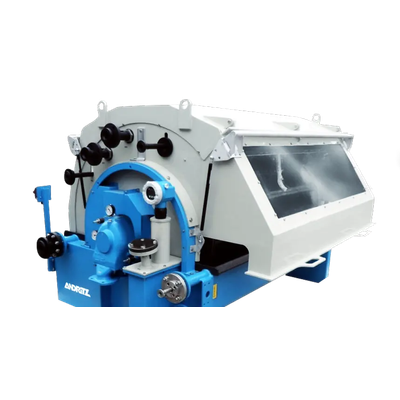

Andritz - Model CORES -Vacuum Drum Filter

The corrosion resistant CORES vacuum drum filter from ANDRITZ is engineered for continuous solid-liquid separation in the most demanding industrial environments. Designed to withstand aggressive chemicals and highly concentrated acids, these rotary filters offer unmatched corrosion resistance, filtration efficiency, and lifetime.

Advanced filtration technology for reliable chemical processing

CORES™ combines decades of ANDRITZ engineering expertise with innovative materials and design. At the heart of the system is a patented sandwich structure composed of glass fiber reinforced plastic (GRP) and non-reinforced polypropylene (PP), forming a seamless, chemically resistant surface. This design eliminates the need for expensive high alloy materials or maintenance-intensive rubber lined filters, while , ensuring long-term durability in highly corrosive conditions.

Materials of construction and improved design for maximum durability

Corrosion resistant filter design

All surfaces exposed to process media are covered with tightly welded thermoplastics, such as PP, PE, PVDF, or ECTFE. This ensures compatibility with a wide range of acids and aggressive slurries. Below a GRP layer provides the needed stability, which is embedded into resin and where needed laminated onto an internal steel structure, minimizing mechanical stresses.

FEM-optimized drum structure

Using Finite Element Method (FEM) simulations, ANDRITZ engineers assure a robust design to withstand the torques across the drum. For highest stability, the shaft, head walls, and trough framework are constructed from steel, GRP, or hybrid materials to balance strength and chemical resistance.

Cake discharge systems for continuous operation

To support uninterrupted processing, CORES™ filters offer multiple cake discharge options:

- Scraper discharge with cake blow-off, suitable for most applications

- Roller discharge for pasty applications

- Belt discharge for products, which tend to recrystallization in the filter cloth, enabling improved cloth washing

- String discharge for sticky products

These discharge mechanisms are tailored to the specific characteristics of the filtered material, enhancing production yield and reducing downtime.

Vacuum operation and process flexibility

The vacuum drum filter operates under a controlled vacuum that draws liquid through the filter medium while retaining solids on the drum surface. The vacuum level, drum speed, and cake thickness are adjustable to meet process requirements, ensuring optimal separation and energy efficiency. Depending on the cake washing requirements, a dedicated number of cake washing pipes can be installed, which ensures the efficient removal of undesired chemicals, such as e.g. chlorides.

Maintenance and lifecycle benefits

Thanks to its corrosion-proof design and modular construction, the CORES™ filter requires minimal maintenance. Welded surfaces prevent leakage and degradation. Even the agitator is mounted outside of the process area, which reduces wear and simplifies servicing. This results in lower total cost of ownership and extended operational life.

Automation in filtration with Metris addIQ

ANDRITZ integrates its Metris addIQ control system to enhance filtration control. Features include:

- Real-time monitoring of process parameters

- Predictive maintenance alerts

- Automated cleaning and discharge cycles

- Integration with plant-wide control systems

This intelligent automation ensures consistent performance, reduces human error, and maximizes uptime. Learn more about Metris addIQ control systems.

- Exceptional corrosion resistance through patented GRP/PP sandwich design

- Reliable operation and long stand times in high demanding applications (e.g. pH value 0 or 1)

- High filtration and cake washing efficiency even for fine particles

- Versatile cake discharge options (scraper, roller, belt, string) for various applications

- Adjustable process conditions for continuous solid-liquid separation under vacuum

- FEM-optimized design for mechanical stability and long service life

- Low maintenance requirements due to seamless, welded surfaces and proven design

- Wide chemical compatibility with PP, PE, PVDF, ECTFE materials

- Guaranteed process performance based on test work

- Sizing and supply of filter peripherals, such as filtrate receivers, filtrate pumps and vacuum systems

- Sustainable process set up thanks to possible counter-washing

- Smart automation via Metris addIQ for process control and predictive maintenance

- Proven performance in industrial applications

- Backed by ANDRITZ engineering expertise and global support

The CORES™ series delivers high throughput and precision. Processing parameters are:

- Filtration capacity: 100–2,000 l/m²/h

- Solids throughput: Up to 1,500 kg/m²/h

- Particle size range: 1–300 µm

- Operating temperature: Up to 80°C (PP-based design)

- Washing ratio: Up to 3:1 (water to dry solids)

- Filtration area: Up to 27 m² per unit