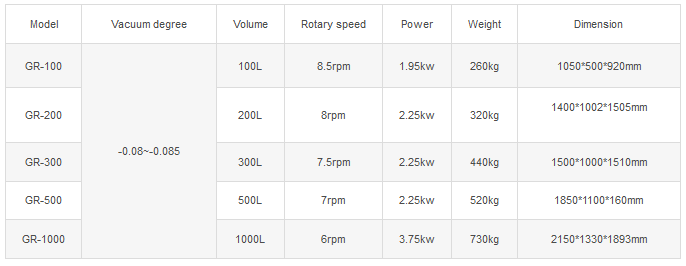

Kingston - Model GR -Vacuum Meat Tumbling Machine

It is a must-have meat processing equipment in the tumbling of meat. The vacuum marinated machine is mainly used to tumble meat in vacuum condition, to a great extent, promoting marinade solution penetration.

- vacuum tumbler is a combination of marination and tumbling. It is a new technique developed by Kingston Team, to accelerate marinade transport throughout the meat.

- the vacuum tumbling machine improves color stability and tenderness of the meat.

- marination mixtures can be evenly applied to the meat through vacuum tumbling, causing alteration in muscle tissue.

- vacuum tumble marination makes meat juicier and faster cooking.

The working principle of the vacuum tumbler: The vacuum tumbler is in the vacuum state, the material is expanded after being negatively pressured, and at the same time, the marinade is evenly distributed in the meat and fully absorbed by the circular massage, beating, and standing of the paddle.

Meat tumbling preparation:

- Placing meat in the vacuum tumbler;

- The corresponding volume of marinade.

Meat rotate in drum, falling and making contact with marinade and metal paddles. The physical rolling process could tumble marinate all boneless skinless breast meat under vacuum pressure, and consequently causes increased marinade uptake in the meat.

- It is in the vacuum status, meat in the drum impacting, turning and rolling, beating, make the meat messaging, marinating, and tumbling, and pickling absorbing flavoring enough, increasing the meat quality, soft and fresh, increasing yielding rate, keep meat quality.

- Free setting tumbling time and interval tumbling time, vacuum status tumbling time, realizing continuously tumbling, setting at will.

- Control panel water proof, touch screen controlling.

- Tumbling space big and reasonable, polished drum and no dead angle, discharging device available discharging water completely.

- Agitating vane circular arc design, distributing material average, not hurt meat appearance

- It is always for meat food process, sausage, ham, hotdog, kebab, spiced meat, etc.

- Tumbling can improve the tissue structure of the meat, increase the binding force and water retention of the meat, and increase the elasticity and yield of the meat.

- The vacuum tumbler can fully contact the protein in the tenderized raw meat with salt water, accelerate the dissolution and interaction of the protein, increase the adhesion between the meat and the meat, and can make the meat Color development, improve meat tenderness and water retention.

- Vacuuming during the tumbling process helps to reduce the increase in meat temperature and the generation of bubbles due to friction. At the same time, the growth and remeation of microorganisms are inhibited, and the pickling effect and yield are improved.

- Rolling and kneading meat under vacuum will reduce heat generation when the meat is rubbed or beaten. Meat will not be oxidized under vacuum, so the meat will not deteriorate during the tumbling process.