- Home

- Companies

- Nederman National Conveyors

- Products

- Vacuum Pneumatic Metal Chip Collection ...

Vacuum Pneumatic Metal Chip Collection & Conveying

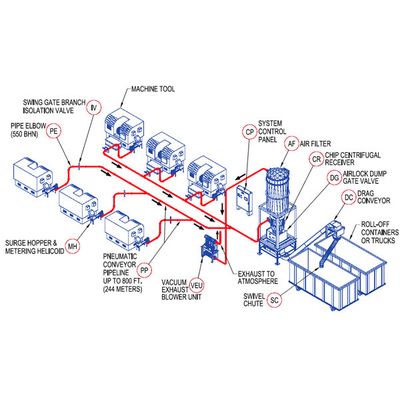

Metal chips are sequentially collected from multiple collection points, such as machine tools, by a vacuum pneumatic conveying system which transports them through pipelines to a central receiving station where they are separated from the induced air flow and discharged into a disposal container storage bin or automatic loadout system. The conveying air flow generated by a mechanical exhauster is filtered prior to discharge into the atmosphere.

Metal chips discharging from individual machine tool conveyors, or from conveniently located transfer stations, are delivered to a pick-up station consisting of a chip surge hopper (MH), metering screw feeder and mixing type intake device. An optional level sensor in each surge hopper signals the vacuum pneumatic conveying system network when a sufficient volume of metal chips have accumulated for conveying. When such signal is received, or by signal of an automatic sequence timer, a pneumatically activated anti-jam swing gate isolation valve (IV) (located just downstream from the pick-up station) opens, exposing vacuum conveying air flow. Simultaneously, the pick-up station (helicoid screw) feeder (MH) begins metering metal chips into the chip intake from which they are rapidly evacuated by the induced air flow and delivered to the downstream receiving equipment.

The incoming air stream reports to a wear resistant cyclonic or radial inlet (receiver) (RH) made of highly abrasion resistant materials where separation of chips from the air flow is accomplished.

The airflow rising from the receiver passes through a high efficiency pulse jet type dust collector/filter (AF) for removal of remaining finely sized metal chip particulates, after which the airflow will be suitable for discharge into the atmosphere.

Metal chips separated by the receiver together with particulates collected by the pulse jet filter report by gravity to a hopper fitted with an airlock type dump gate valve (DG) for discharge.

The National vacuum pneumatic metal chip conveying system offers these benefits:

- No Chip Tub Forklift Traffic or Labor Required

- Modular Design - Easily Adaptable to Different Machine Layouts, Extended or Reconfigured

- Economical Installed Cost

- Minimal Space Requirement

- Clean Working Environment, No Dusting

- Low Maintenance