Variant Factory Ltd.

- Home

- Companies

- Variant Factory Ltd.

- Products

- Variant - Model UNIFORM - Configurable ...

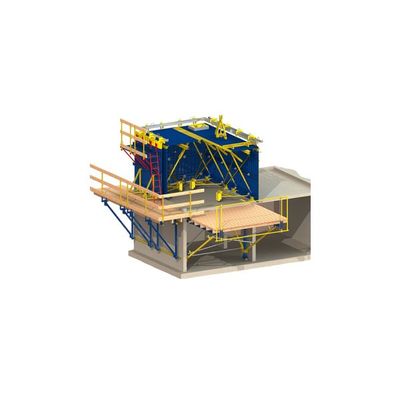

Variant - Model UNIFORM -Configurable Tunnel System

Tunnel Formwork is a system which allows simultaneous casting of walls and slab in one pouring cycle. Half tunnels can be stripped and moved out to the next phase/level the nest day after the pouring. Having faster workflow and being easier to operate with, compared to conventional systems, use of the system can save up to 50% of formwork budget. The system enables you to have smooth concrete surface, dimensional accuracy and eliminates finishing works like plastering. Moreover the system creates good load-bearing concrete structure, which can be applicable for projects in seismic areas.

Most popular related searches

Load-bearing capacity:

- High load-bearing capacity.

Cost-effective:

- Rapid pace of work and cutting of re-assembly cost due to the repositioning of complete units;

- High quality of concrete surface minimizes finishing work;

- High number of use cycles (up to 500) means lower follow-up expenses.

Easy handling and planning:

- Small number of different parts is used;

- Time and cost-effective owing to use of preassembled half tunnels;

- The formwork can be plumbed and aligned very quickly and accurately in all directions.

Safe use:

- Safe working conditions provided by systems safe equipment.