- Home

- Companies

- Veenstra Technology

- Products

- Veenstra - Model CA Series - Mobile ...

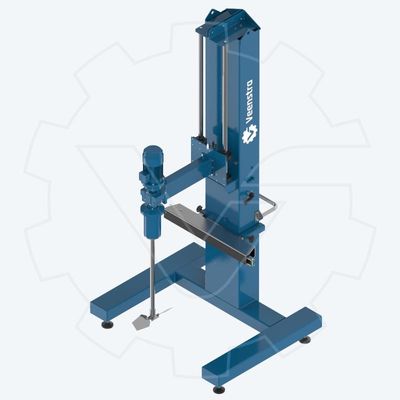

Veenstra - Model CA Series -Mobile Column Mixers

Movable column mixers can be moved around and custom manufactured to optimise your processes. This type of mixer is equipped with support legs, hoisting facilities or fork pockets. These mixers are extremely suitable for mixing different viscosities and temperatures.

The choice of a mobile column mixer is obvious: when your production process requires a high degree of flexibility.

For example, do you want to effortlessly place a mixer in different positions? Or use a mixer in one room and then again in another room without much hassle? Or do you want to use a mixer during batch production and quickly mix different barrels in a row? In all those cases, a mobile column mixer provides the solution.

We list the benefits of a mobile column mixer below.

- Easy to move or roll Mobile mixers are easy to move or roll, which makes batch production of liquids in different barrels less complex and more efficient. Switching between rooms also becomes easier.

- No anchoring required Unlike static column mixers, mobile column mixers do not require anchoring to the floor or wall.

- Fully adaptable to different process flows Accurate and efficient mixing is important in many production processes. Mobile column mixers can be fully tailored to your process and are easy to place in your production line. Thanks to our broad knowledge and experience, we can deliver robust mixers that are tailor-made for your production process and meet your specific requirements and any regulations applicable in your industry. In the production of our mixers, we only use high-quality materials that meet strict quality standards.

- Widely applicable and applicable Every industry has its own requirements for industrial mixers, and every application requires custom process equipment. Mobile column mixers can be sized for any volume flow, density, viscosity, and other substance-specific properties, making them suitable for economically mixing or blending chemicals, wastewater, coatings, paint, and other liquids. This makes mobile column mixers ideal for a wide range of industrial applications.

There are several disadvantages to a mobile column mixer compared to a static column mixer with the same capacity.

- Takes up relatively more space Compared to a static column mixer with the same capacity, a mobile column mixer takes up more space. This is because a mobile column mixer requires a stable subframe and is not anchored to the floor, wall, or structure like a static mixer.

- Can be executed less heavily A static column mixer can be executed much heavier than a mobile mixer. At some point, the agitators become so heavy that stability is endangered without anchoring.

Mobile column mixers are industrial mixers that are similar to static column mixers but differ in their mobility. They are relatively easy to move or roll, making them ideal for use in a wide variety of production lines and spaces.