VeriPac - Model 400 Series -Packaging Test Systems

VeriPac test systems are non-destructive, non-subjective and require no sample preparation. Test fixtures are designed to inspect flexible, rigid and semi-rigid packaging. VeriPac inspection systems use cutting edge innovation to provide repeatable, more sensitive, and more robust detection of defects.

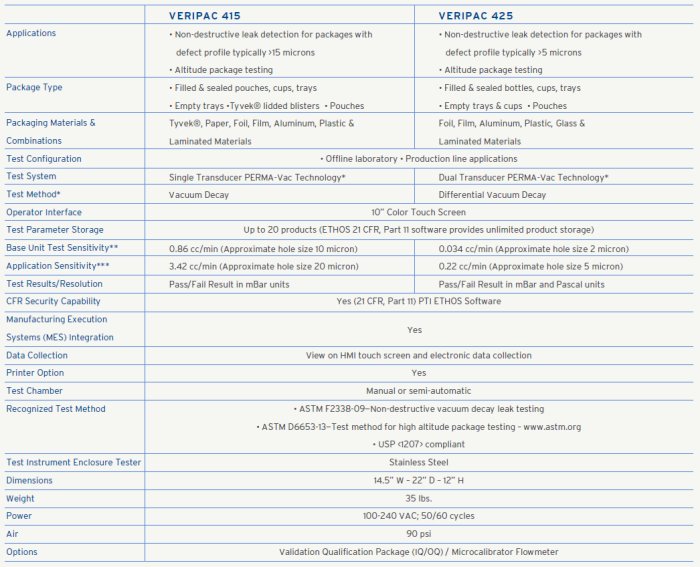

VeriPac inspection systems utilize an ASTM approved vacuum decay leak test method F2338, which is listed in ISO 11607, USP <1207> and is a FDA recognized consensus standard for package integrity testing. This ASTM method was developed using VeriPac leak test instruments and has proven its capabilities under GMP regulatory guidelines. Applications for VeriPac technology include stability studies, clinical trials, quality assurance testing and statistical process control (SPC). VeriPac testers feature the patented PERMA-Vac manifold system and dynamic test modes that provide the ability to test a wide range of package formats.

Leak detection of high risk applications requires the highest level of test measurement reliability. The VeriPac series has redefined the reliability and accuracy of test measurement systems.

- Deterministic, quantitative test method

- Defect detection down to 0.034 cc/min.

- Highest level of repeatability andaccuracy

- Cost effective with rapid returnon investment

- Simplifies the inspection andvalidation process

- Results proven superior to dye ingress

- ASTM test method and FDA standard

- USP <1207> Compliant

- Measures seal integrity of entire container or package

- Measures and verifies container closure integrity

- Altitude package testing

VeriPac leak testers connect to a test chamber that is specially designed to contain the package to be tested. The package is placed inside the test chamber to which vacuum is applied. The single or dual vacuum transducer technology is used to monitor the test chamber for both the level of vacuum as well as the change in vacuum over a predetermined test time. The changes in absolute and differential vacuum indicate the presence of leaks and defects within the package. The sensitivity of a test is a function of the package design, the package test fixture and critical test parameters of time and pressure. Test systems can be designed for manual or automatic operation. This inspection method is suitable for laboratory offline testing and production applications for QA/QC statistical process control. The test cycle takes only a few seconds, is non-invasive and non-destructive to both product and package.