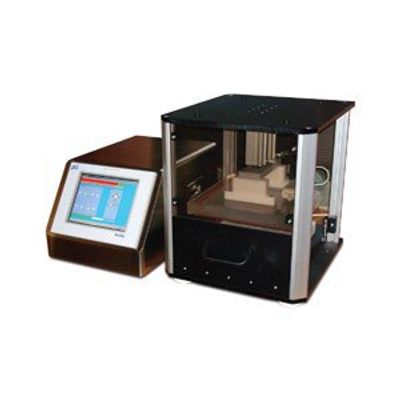

VeriPac - Model 410 -Packaging Inspection System

The VeriPac 410 inspection system offers non-destructive seal and leak detection for blister packs, sachets, and pouches with low headspace. Multi-cavity blister packs and low head space packaging use a variety of test methods to determine package integrity, with most being destructive, subjective, and unreliable.

The VeriPac 410 utilizes a combination of vacuum decay technology and differential force measurement to identify defective packages. Depending on the package specifications, the 410 provides the capability to test multiple packages in a single test cycle. The VeriPac 410 also identifies which package or blister cavity is defective. Test results are quantitative and provide operators with a definitive pass/fail result.

Package quality assurance is achieved by deploying accurate, reliable, non-destructive inspection methods that remove subjectivity from the testing process. The VeriPac 410 allows tested product to be returned to the production line and eliminates the cost and waste associated with destructive leak test methods. The 410 addresses all issues associated with low volume flexible and semi-flexible package leak testing. The ROI for the VeriPac 410 makes this a powerful solution for the pharmaceutical industry.

- Non-destructive, non-invasive, no sample preparation

- Non-subjective, accurate and repeatable results

- Capability to test multiple packages in a single test cycle

- Identifies which package is defective

- Simplifies the inspection and validation process

- Supports sustainable packaging initiatives

- ASTM test method and FDA standard

- Cost effective with rapid return on investment

The VeriPac 410 tester is connected to a specially designed drawer-style test chamber. A custom package insert that conforms to the package shape increases test sensitivity. Certain types of packages can be tested in multiple during a single test cycle. The location of the defective package or cavity is identified. Vacuum levels are monitored during the test cycle to evaluate the package using the ASTM F2338 vacuum decay leak test method. Decay of the vacuum level indicates that air is leaking from the package into the test chamber.

Once the vacuum testing phase is complete, a pressure plate maps the surface pressure of the flexible package lidding. The pressure plate system recognizes the pressure pattern exerted by the package when it is not defective, and the lack of pressure exerted on the pressure plate by a defect, allowing for both defect detection and location of the defective package or cavity.

- Leak detection and seal integrity testing of entire package

- Test sensitivity down to 15 microns

Application

- Non-destructive leak detection of blister packs, sachets and pouches with low headspace

- Defect profile typically > 15 microns

Package Type

- Blister packs

- Sachets

- Pouches with low headspace

Package Materials: Non-porous materials: foil, plastic, poly, film, Aluminum, paper

Offline or Online: Offline lab instrument

Test Method*

- Absolute vacuum transducer

- Pressure plate

Technology: Vacuum decay and differential force measurement

Operator Interface: 10” Color Touch Screen

Test Parameter Storage: Up to 20 packages

Test Result Data: Pass/Fail Result in mBar units

Test Sensitivity: 2 ccm (approximate hole size 15 microns)

Security Password: Yes

Remote Internet Access: Yes

Data Collection: View on touch screen and electronic data log collection

Test Chamber: Test drawer configuration

ASTM Test Method: ASTM F2338-09**

Test Instrument Enclosure: Stainless Steel

Test Chamber Inner Dimensions: Maximum test area 240 mm x 240 mm

Test Dimensions/Weight: 14.5” W x 22” D x 12” H/35 lbs.

Test Drawer Footprint: 17” W x 21” D

Power: 100-240 VAC;50/60 cycles

Air: 90 psi

Options: Validation Qualification Package (IQ/OQ/PQ) / Microcalibrator Flowmeter