- Home

- Companies

- Zhangqiu Tony Made Machinery Co., Ltd.

- Products

- Vertical Ring Die Pellet Mill-Bigger ...

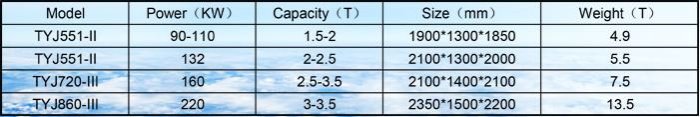

Vertical Ring Die Pellet Mill-Bigger Gear Transmission

To be continued for all the advantages of big gear Transmission ring die pellet mill TYJ550-III. Cancel reducer coupling, vertical motor with big gear transmission combined. Adopting motor shaft and big gear shaft direct connection. Stronger power transmission and greater anti-torque makes machine more stable and lower maintenance rate for reducer. Improve bearing chamber processing technique: A. Change bearing chamber, replaced the seal mode and forging conditioning wear-resisting material which can avoid the dust dropping into bearing chamber. B.Changing the bearing chamber, obsoleted the traditional grease lubrication style. Firstly using adjustable timer butter filling lubrication system and adding grease alarm device to avoid wasting for grease which will save the grease cost by at least 3000 USD/Year.

- Adding electric control alarm device inside reducer lubrication system. The larm bell rings to stop machine immediately when the oiling is blocked. Lubrication for reducer is more intelligent.

- Increasing few times for spindle loading parameter. Spindle design technique is more precise. Electric heating no hitting installation makes the spindle has longer working life.

- Certified HH-HRB bearings which has longer working life. Maintenance rate for the whole machine is lower.