- Home

- Companies

- Kansas City Deaerator Company

- Products

- Vertical Tray Deaerator (Single ...

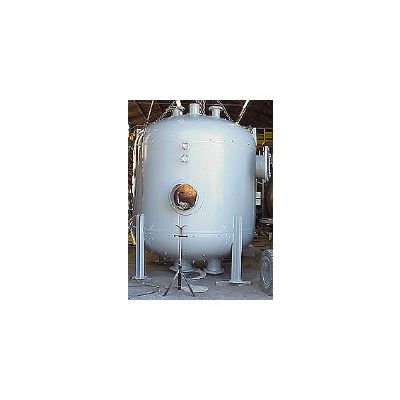

Vertical Tray Deaerator (Single Vertical Tank)

Corrosion is caused by the presence of non-condensable gases such as oxygen and carbon dioxide in water. In order to remove the non-condensable gases, the feedwater is heated and vigorously scrubbed by a counter current flow of steam. The incoming undeaerated water enters the deaerator though spring-loaded, stainless steel spray valves. These variable orifice valves produce a fine spray in a uniform pattern from 5% to 200% of design. The fine droplets of water maximize the surface area in contact with steam, raising the temperature to within a few degrees of saturation temperature and instantly releasing the majority of the corrosive, non-condensable gases.

The preheated and partially deaerated water flows through the tray stack where the hottest, purest steam vigorously scrubs the water to heat it to saturation temperature and strips the last traces of dissolved gases.

The entire deaeration process takes place in a stainless steel enclosure that eliminates any need for vessel lining or cladding and ensures a long life with little maintenance.