- Home

- Companies

- Dongguan Vnovo New Material Technology ...

- Products

- Vnovo - Contact Grease

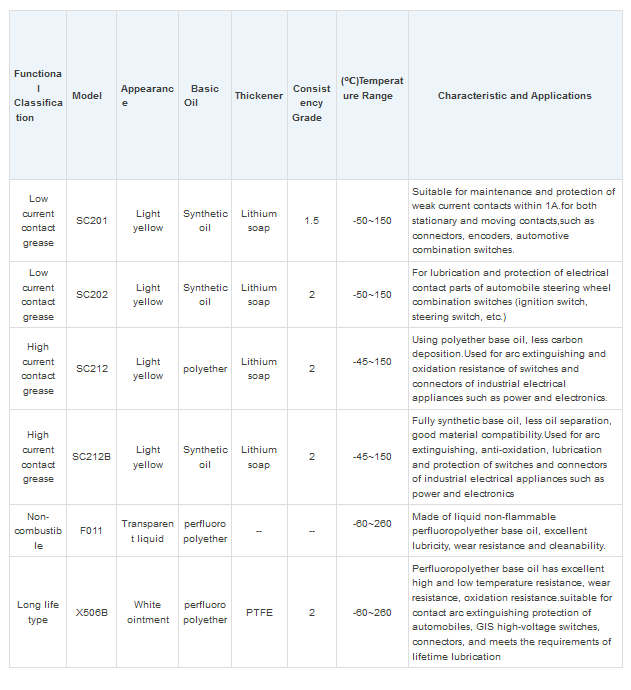

Vnovo - Contact Grease

Electrical contacts are key components of various switches, connectors, relays, jack plugs, circuit breakers, commutators, etcBy adding appropriate grease, the lubrication state of each friction surface of the switch can be effectively improved, the wear is suppressed, the arc is reduced, the temperature rise is reduced, the oxidation is prevented, the controllability and feel are improved, and the service life is prolonged.

Under the naked eye, the switch surface is very smooth.While under the microscope, the switch surface is quite rough.Therefore, under the influence of different contact forces, the effective contact area of the switch is only 0.01% to 1% of its surface area (picture 1a,1b)This very small contact area determines the size of the contact resistance.

In many cases, a layer of metal oxide or plastic decomposition often forms on the contact surface, increasing the contact resistance.This oxide layer, which usually breaks down when the contacts are stressed enough or heated enough to form.However, the heat generated will exacerbate microseismic corrosion, resulting in a further rise in contact resistance.After removing the oxide layer, the actual effective contact area left behind becomes a-spot{like picture 1 c)

At the same time, during the continuous opening and closing process of the switch, due to the existence of friction and wear, in the absence of lubricant, the actual effective contact area will continue to decrease, which is directly reflected in the continuous increase of the contact resistance of the switch, which ultimately affects its actual use.

Requirements for Selecting Contact Grease:

- Excellent wear resistance and lubricity, can prevent the contact surface from oxidation and reduce wear, improve the switch operation feel.

- Excellent arc extinguishing ability to prevent sparks and carbon deposits from contact contacts.

- No dripping oil at high temperature, no solidification at low temperature.

- Excellent oxidation resistance and anti-electrochemical corrosion resistance, significant moisture resistance, anti-salt spray performance.

- Excellent metal rust and corrosion protection, good compatibility with most plastics and elastomers.