- Home

- Companies

- TOP Machinery(Chengdu) Co., Ltd

- Products

- Top-Machinery - Model TPNDL - Volute ...

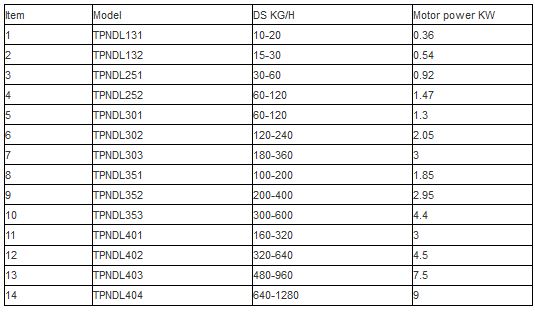

Top-Machinery - Model TPNDL -Volute Screw Sludge Thickener

Volute screw sludge thickener inherits the technical advantages of Volute screw sludge dewatering machine like low energy consumption, high efficiency, fully automatic control and stable operation. The sludge from secondary sedimentation tank can be condensed rapidly and continuously, and the sludge concentration can be adjustable within the range of 90%~96% after concentration and separation. After using this equipment, a concentration tank is not necessary, construction investment and land occupation can be reduced, the odor and phosphorus release caused by the concentration tank can be effectively reduced, the burden of subsequent processing can be reduced and the capacity of sludge dewatering and deep dewatering equipment can be significantly increased.

- Model:TPNDL

- Price:Non - standard customized

- Package: Wooden box

- Place of Origin:China

- Minimum order quantity:1 Set

Volute screw sludge thickener consists of concentrator, driving device, filtrate tank, mixing system, and frame. The working process is that the sludge is lifted to the mixing tank by the sludge pump. Meanwhile, the dosing pump also quantitatively delivers the chemicals to the mixing tank, the stirring motor drives the entire stirring system to thoroughly mix the sludge and the chemicals, thus coagulates into larger flocs. When the liquid level reaches the upper position of the liquid level sensor, the chemical sensor gets a signal so that the motor of the screw press works, thus start to filter pressing the sludge into the screw sludge body. Under the action of the screw shaft, the sludge is lifted to the sludge outlet step by step, and the filtrate flows out from the gaps between the fixed rings and moving rings.

In a word, volute screw sludge thickener is using the principle of spiral extrusion. Through the strong squeezing force generated by the pitch change and the tiny gaps between the moving rings and fixed rings, the sludge can be squeezed and concentrated to achieve solid-liquid separation. It is a new equipment for solid-liquid separation.