Walle Industry

- Home

- Companies

- Walle Industry

- Products

- Walle - Model Pulse Series - Dust ...

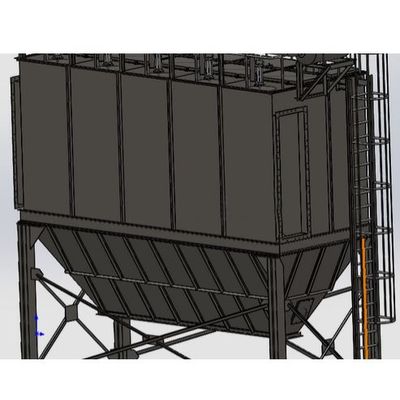

Walle - Model Pulse Series -Dust Collector

FromWalle Industry

Pulse dust collector is a new type of high-efficiency pulse dust collector improved on the basis of mc-i. It has the advantages of high purification efficiency, large gas processing capacity, stable performance, long service life of filter bag, convenient operation and small maintenance workload.

Most popular related searches

dust collector

pulse dust collector

flue gas sampling

hot flue gas

dust control

filter bag

flue gas

cement industry dust

dust cleaning

gas purification

This series of dust collectors are especially suitable for the following occasions: calcium carbide furnace dust removal, various electric furnaces dust removal in ferroalloy plant; Flue gas purification of iron and steel plant; Dust removal of coal-fired boilers and small boilers in power plants; Dust removal of waste incinerator; Dedusting of high temperature flue gas in smelter; Flue gas purification of aluminum plant; Dust removal at kiln tail and kiln head of rotary kiln in cement plant; Dust removal of tail gas from carbon black plant, etc.

What we offer

- By adopting the pulse jet dust cleaning technology of compartment air stop, the shortcomings of conventional pulse dust collector and compartment back blowing dust collector are overcome. It has strong dust cleaning capacity, high dust removal efficiency, low emission concentration, small air leakage rate, less energy consumption, less steel consumption, less floor area, stable and reliable operation and good economic benefits. It is applicable to the purification of dusty gas and material recovery in metallurgy, building materials, cement, machinery, chemical industry, electric power and light industry.

- Due to the use of compartment stop air pulse injection for ash cleaning, the purpose of complete ash cleaning can be achieved by one injection. Therefore, the ash cleaning cycle is prolonged, the ash cleaning energy consumption is reduced, and the air pressure consumption can be greatly reduced. At the same time, the fatigue degree of filter bag and pulse valve is reduced accordingly, so as to double the service life of filter bag and valve plate.

- The maintenance and bag replacement can be carried out in different rooms under the normal operation condition of the system without stopping the system fan. The opening of the filter bag adopts elastic expansion ring, which has good sealing performance and is firm and reliable. The keel of the filter bag is polygonal, which reduces the friction between the bag and the keel, prolongs the service life of the bag and is convenient for bag unloading.

- The upper bag pumping method is adopted. After the skeleton is pulled out during bag changing, the dirty bag is put into the ash hopper at the lower part of the box and taken out from the manhole, which improves the operation conditions of bag changing.

- The box body adopts air tightness design with good sealing performance. The inspection door uses excellent sealing materials. Kerosene is used to detect leakage in the manufacturing process, and the air leakage rate is very low.

- The inlet and outlet air ducts are arranged compactly and the air flow resistance is small