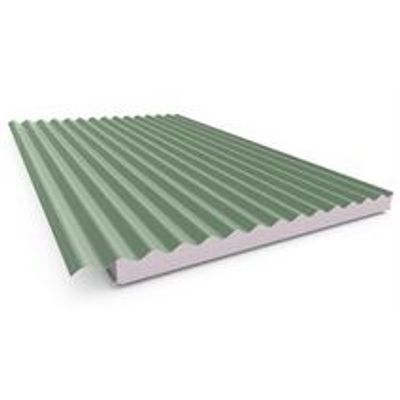

Wanzhi - Steel Sandwich Panel

Steel sandwich panel is a common building material with great heat and sound insulation. It also keeps the features of color steel, like high strength, excellent corrosion resistance, easy installation, light in weight, less maintenance, and attractive appearance. It is widely used in the roof and wall systems of industrial plants, warehouses, gymnasiums, supermarkets, cold storage, mobile houses, and other applications. Wanzhi Steel offers GI, GL, PPGL, PPGI sandwich panels with different designs, core materials, specifications, colors, and patterns, etc. Welcome to contact us for a free quote.

Steel Sandwich Panel Uses

Insulated sandwich panels are extensively used as roofing or wall panels, from factories to malls, such as:

- Industrial Buildings

- Cold Storages

- Agricultural and Husbandry Buildings

- Worksite Buildings

- Residential Buildings

What Is Sandwich Panel?

A sandwich panel is made with a core of thermal insulating material and covered with two pieces of metal sheets. Our sandwich panels use GI, GL, PPGI, PPGL steel sheets. Generally, the types of sandwich panels are grouped by core materials, for example, EPS (expanded polystyrene), PIR, RW, XPS, PU, and PF. The main differences between them lie in their fire resistance, sound-heat-insulating performance, etc.

- Steel Sheet Material GI, GL, PPGI, PPGL

- Steel Sheet Thickness 0.2-1.0 mm

- Length Customized as per your requirements

- Common Effective Width 950 mm-1150 mm

- Thickness of Core Material 50 mm-200 mm

- Design Wavy, trapezoidal, tile, etc.

- Core Material EPS, XPS, PU, PIR, PF, RW

- Features 1. Good heat and sound insulation 2. Excellent fire resistance

- 3. Easy Installation 4. Wide applications

Easy Installation

Its lightweight and beautiful appearance make it easy to install. There is no need for secondary processing, which can shorten the construction period. A building using the traditional material may take 6 to 7 months to complete. While if using steel insulated sandwich panels, it needs only 1 to 2 months.

Durability

The corrugated sandwich panel keeps the strength of steel, which is strong and durable to use. Both PPGI PUF panels and GI sandwich panels are corrosion resistant so that they are suitable for different use environments. Also, it is almost free of maintenance.

Heat & Sound Insulation

Compared to the PPGI roofing sheet, PPGI sandwich panels has excellent thermal resistance. The λ-values range from 0.024 W/(m·K) for polyurethane to 0.05 W/(m·K) for mineral wool. It is suitable for both extreme cold or hot conditions.

High Fire Resistance

A sandwich panel will slow down the spreading of fire to ensure the safety of life and property in the building. Please note that for fire insulation aims, you need to take the core material into consideration.