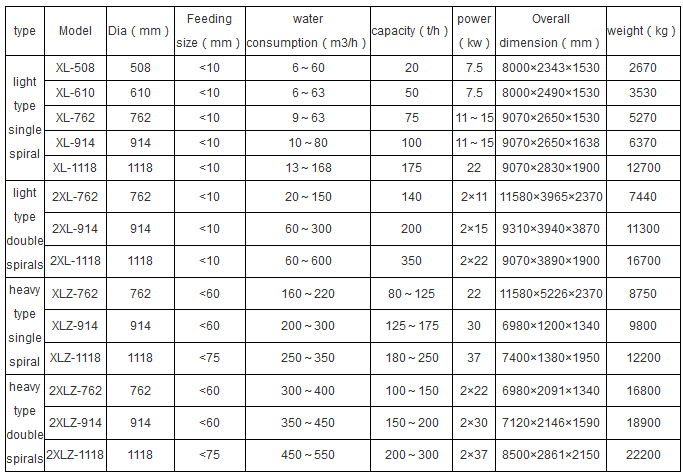

Henan-Zhongke - Model XL Serie -Washing Machine

XL Series washing and selecting machine is applicable to metallurgy, building materials, water and electricity industries such as washing, grading, purify and other operations. light type of This series is suitable to fine materials , while heavy type of this series is suitable to washing and selecting coarse-grained materials .

XL Series Washer machine, motor through a triangular belt, reducer, gear reducer driven impeller to rotate slowly, gravel by the feed chute into the washing groove, rolling in the impeller drive, and grinding each other, remove the impurities on the surface of the sand covered and destroy coated sand moisture layer, in order to facilitate the dehydration; while adding water, forming strong currents, timely will take a small proportion of the impurities and the foreign body, and wash tank is discharged from the overflow outlet to complete the cleaning. Clean sand from the leaves away, finally gravel from the rotation of the impeller into the trough, to complete the cleaning effect of gravel。

Washing equipment is widely used in metallurgy, building materials, water and electricity industries such as washing, grading, cleaning and other operations, can also apply to the construction site, sand factory, desliming operation of precast concrete plant and a large number of hydropower construction sand, also can be used for washing, the ore grade, dehydration can be carried out in the washing machine. Washing, can also be used in screening and classification equipment. The washing operation is suitable for fine-grained and coarse-grained materials. For building sand, sand road for drum washer is reasonable in structure, convenient maintenance, large capacity, small power consumption, high cleanliness. Sealing structure is novel, fully enclosed oil bath type transmission device, adjustable overflow weir plate, ensure the products efficient, durable, cleaning, dehydration, fine product stability.

- High level cleaning, reasonable structure;

- High productivity, small power dissipation;

- Small loss of sand in the process of sand washing;

- Much lower malfunction rate.