chengdu purui polymer engineering co.,ltdPurui Plastic & Rubber Machinery Co., Ltd

- Home

- Companies

- chengdu purui polymer engineering ...

- Products

- Purui - Model ML - Waste Polyester ...

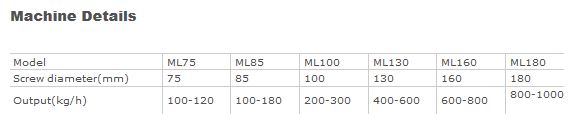

Purui - Model ML -Waste Polyester Pelletizing Plant and Textile Recycling Machine

PET yarn with 45% moisture--belt conveyor-single shaft shredder--screw loader--ML main pelletizing plant--PET fiber pelletizing system--manual packaging system

Most popular related searches

pellet plant

single shaft shredder

plastic pelletizing plant

textile recycling system

pelletizer

pelletizing

plastic pelletizing

plastic pelletizer

belt conveyor

pelletizing system

General Introduction:

First , to put the PET yarn with 45% moisture into the belt conveyor, and to feed single shaft shredder for pre-crushing prcoess.

The crushed PET yarn get transfered by screw conveyor from the centrifugal dewatering to dehydrate. The dewatering machine capacity is about 500kg/h. One time dewatering takes 4-5 minutes.

After ewatering system, the present PET fiber is in 1-2% moisture. Now, the operator can go on pelletizing textile/ yarn/polyester with the help of ML130 plastic pelletizing plant.

Machine operator can put into the PET yarn bale into the conveyor directly. The conveyor charges the dewatering PET yarn into compactor. The compactor will further pre-cut and preplastification the material by the fixed cutter and rotary cutter friction. It will enhance machine cutting ability, fiber/yarn.polyester get further drying.

with ML140 main extruder heating and melting, PET fiber/yarn get melt with output nice pellet. the final pellets get packaged by the packing system.

The crushed PET yarn get transfered by screw conveyor from the centrifugal dewatering to dehydrate. The dewatering machine capacity is about 500kg/h. One time dewatering takes 4-5 minutes.

After ewatering system, the present PET fiber is in 1-2% moisture. Now, the operator can go on pelletizing textile/ yarn/polyester with the help of ML130 plastic pelletizing plant.

Machine operator can put into the PET yarn bale into the conveyor directly. The conveyor charges the dewatering PET yarn into compactor. The compactor will further pre-cut and preplastification the material by the fixed cutter and rotary cutter friction. It will enhance machine cutting ability, fiber/yarn.polyester get further drying.

with ML140 main extruder heating and melting, PET fiber/yarn get melt with output nice pellet. the final pellets get packaged by the packing system.