Shangqiu Sihai Energy Technology Co., Ltd

- Home

- Companies

- Shangqiu Sihai Energy Technology Co., ...

- Products

- Sihai - Waste Tire/ Rubber Pyrolysis ...

Sihai - Waste Tire/ Rubber Pyrolysis Plant

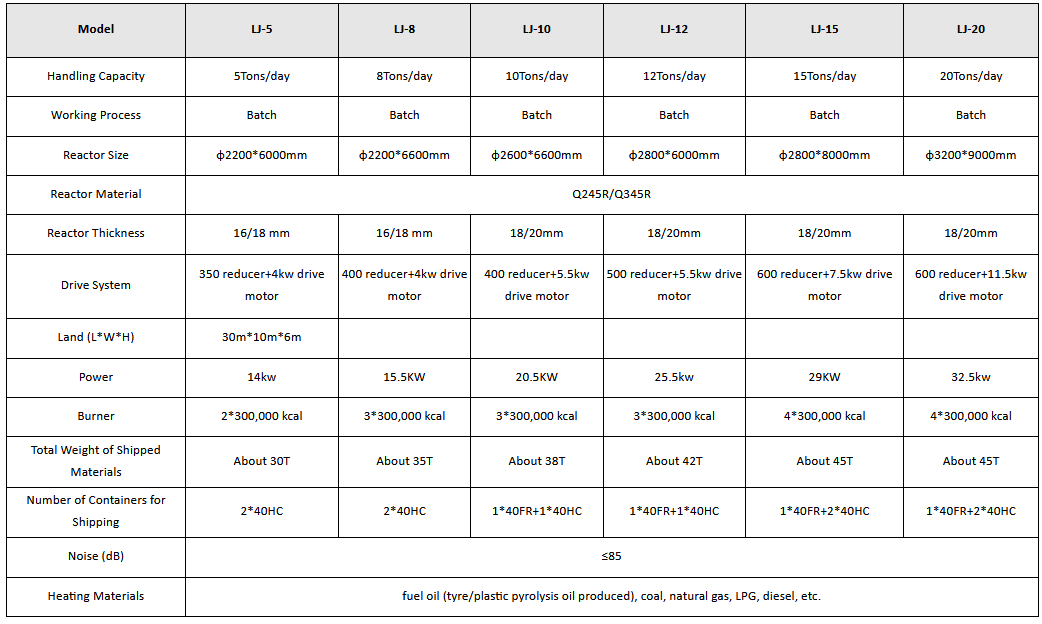

Pyrolysis plant converts waste tyre/rubber into fuel oil by pyrolysis process with handling capacity ranges from 5 tons to 20 tons per day , and produces 45% of pyrolysis oil, 37% of carbon black, 13% of steel wire with high efficiency and low labor cost.

Most popular related searches

waste tire

tire pyrolysis

rubber pyrolysis plant

waste tire pyrolysis plant

rubber pyrolysis

black carbon

gas separation

environmental impact

scrap tire

waste tire pyrolysis

Pyrolysis plant is a cutting-edge solution designed to transform waste tires into valuable resources. This advanced technology employs a high-temperature pyrolysis process to decompose scrap tires, converting them into fuel oil, carbon black, steel wires, and fuel gas. This not only mitigates the environmental impact of black pollution but also facilitates the recycling and regeneration of resources.

- Feeding (2 Hours): Load tires/rubbers into the reactor by automatic hydraulic feeder, after loading all, seal the feeding door.

- Heating ( 8~10 Hours): Start the tire pyrolysis machine and the reactor will be rotating and heated by fuel. When the temperature reaches the degree of 250 to 280, the oil steam will be continuous produced until the temperature reaches 350-480 C. Oil steam will flow through oil gas separator, light component will enter the condensers and liquified as fuel oil, meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as fuel oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material.

- Cooling(4~5 Hours): After the oil producing process is completed, leave the plant for cooling and waiting for discharge.

- Discharging(2 Hours): Discharge the carbon black automatically and pull out the steel wire finally.