Synspec - Water Purge Unit (WPU) for Toxic VOC in Water

Accessory to Measure Volatile Organic Hydrocarbons in Water with a GC. Synspec Water Purge Unit (WPU) has been specifically developed to strip volatile organic hydrocarbons from water, and should be used in combination with a Synspec gas chromatography (GC) system. By using this combination of a WPU with a GC it is possible to determine the concentrations of hydrocarbons in water.

The instrument can be utilised in various applications:

- monitoring industrial waste water

- monitoring by authorities to check surface and ground waters

- monitoring of water used for cleaning contaminated soil

- Size: H 75 cm, Width 40 cm (fits 19”rack), D 21 cm

- Recommended Analysers: Synspec GC955 or Synspec Alpha and Delta lines; internal computer GC controls WPU

A purge and trap unit is now available for the separate individual measurement of volatile organic hydrocarbons in water in combination with the full range of Synspec gas chromatography (GC) systems.

The purge and trap unit has been developed to strip Volatile Organic Compounds (VOCs) with air or nitrogen from water for the continuous qualitative and quantitative determination of up to 40 types of hydrocarbons.

Three main applications are monitoring industrial waste water, monitoring by authorities to control drinking, surface and ground waters, and monitoring during cleaning of contaminated soil.

- Control of raw and cleaned industrial waste water before transferring it further to be certain that the water is not contaminated. This way, for example, pollution of rivers can be prevented.

- Measurement of water quality in surface and ground water to ascertain its quality for various purposes.

- Determining the quality of ground water layers either near contaminated soil sites or during the clean–up process of the soil, where water is often used to remove hydrocarbon contamination.

In the above mentioned cases the monitor water samples can be analysed in a laboratory. However, this process is time consuming and expensive. With online measurements you can react immediately if alarm values are exceeded.

The hydrocarbons that are important to measure are toxic or carcinogenic.

- Aromates: a.o. BTEX (Benzene, Toluene, Ethylbenzene, Xylenes) in combination or as single compounds.

- Chlorinated compounds: chloroform, trichloroethene, tetrachloroethene, tetrachloromethane, 1,2-dichlorethane.

The lowest detection limits are below 1 µg/l.

Water temperatures used are slightly above room temperature, water flow from 3 to 30 l/hr.

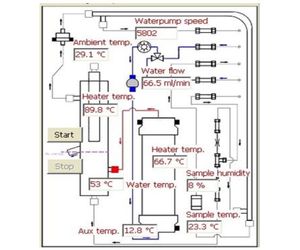

An external pump unit (either already provided by the user or by Synspec) pumps the water from the source. A second bypass pump ascertains a water sample without particles that pass to the purge unit. The sample is heated to a stable temperature.

By purging clean air through this sample only hydrocarbons are stripped from the water layer. Fine particles, salts, soaps and high boiling oils remain in the water layer.

The purge air flow is regulated up to 300 ml/min from a water flow with a capacity from 3 to 30 l/h.

The system has a foam destroyer to avoid foam entering the GC. The WPU is controlled by the computer in the GC.

The full range of the gas chromatographs from Synspec can be used for the analysis: the sample can be analysed for total hydrocarbons in a Synspec Alpha, for one specific hydrocarbon in a Synspec Delta with loop (these applications have detection limits ranging from 30 to 50 ppb). Additionally, up to 40 compounds can be measured with the lowest detection limits below 0,1 ppb with Synspec gas chromatograph with trap.

Cycle times range from 2 to 30 minutes, depending on the application. Separate data sheets are available for the gas chromatograph options.

- Size: H 75 cm, Width 40 cm (fits 19”rack), D 21 cm

- Power Demand: 230V/6A or 115V/12A

- Flow of Water: 100 – 500 ml/min

- Flow of Purging Air: 50 to 300ml/min at 4 bar, zero air generator as option available.

- Water Conditions:

- 5 – 50 oC, cooling optional

- Freeze protection required

- Environmental Conditions

- Temperature 5 – 40 oC,

- relative humidity 20 – 95% rH

- Water (Pre) Filters

- Depends on sample, sand filter, cyclone filter

- Entrance filter 250 um

- Filter Cleaning

- Drinking water once a month, other depending on water particle content

- Mounting

- On wall or in rack, rear access is not needed

- AC Power

- 220VAC 50/60 Hz or 110VAC 50/60 Hz

- Recommended Analysers

- Synspec GC955 or Synspec Alpha and Delta lines; internal computer GC controls WPU