- Home

- Companies

- Watertech of America, Inc.

- Products

- eController - Water Treatment Control ...

eController - Water Treatment Control System

An eController from Watertech of America can take your water treatment control program out of the dark ages. These controllers have the latest, most advanced cooling and boiler water control methods available on the market. That, combined with 21st century remote monitoring capabilities, make this the best controller available on the market today.

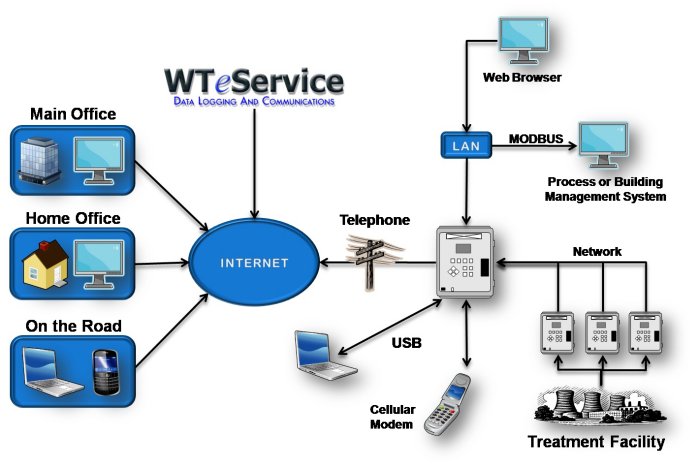

Remote Communication

The boiler and cooling water controllers of the past were stand-alone devices that featured flow-based feed as their most advanced control option. Their ability to provide alarms and process data consisted mostly of an alarm output tied to a building management or SCADA system. The eController provides multiple communication options that allow you to communicate with the controller.

- USB - Any computer with a web browser can connect to the eController via the USB connection that comes standard with every eController.

- Ethernet - Also a standard feature, each eController has an ethernet connection that allows you to connect the controller to your company`s intranet so that it can be accessed from any computer in your business.

- Modem - As an option, the eController can be configured with a modem. This is a great option when IT security does not want the eController to be on a company intranet. You can still access the controller from any computer with an internet connection by using the manufacturer`s ShoulderTap service.

- MODBUS TCP/IP - Also as an option, the eController can be configured with MODBUS TCP/IP for connecting to building management, distributed control, process management and SCADA systems.

Once your eController is connected to the internet, it has the ability to send status updates, datalog reports, and alarms to email addresses or cell phone text numbers.

Advanced Cooling Tower and Boiler Controllers

An eController from Watertech of America can take your water treatment control program out of the dark ages. These controllers have the latest, most advanced, cooling and boiler water control methods available on the market. That, combined with 21st century remote monitoring capabilities, make this the best controller available on the market today.

Data Logging

Managing any process requires the operator to collect data, process that data, and use it to make good operational decisions. The eController provides your water system operators and managers with a tool that allows them to gather data related to your boiler, cooling and wastewater systems. The internal memory of the eController can store up to a month`s worth of data (depending upon the number of inputs and how often the data is logged). This data can be sent automatically via email or manually by connecting the eController to a computer via the USB connection. The data is provided in a format that is easily imported into almost any spreadsheet software where you can create reports and graphs. In addition, there is an internal Graphing and Trending capability that allows you to get a quick look at any of the data when you are connected to the controller.

WTeService Integration

To take data logging to the next level, our customers have the ability to connect their eControllers to our WTeService site. By doing this, your data is transmitted to WTeService on a regular basis. The advantages to this include:

- No need to download data -collects and stores all of your process data, thus eliminating the need for you to store the data

- Web-based data analysis - provides a web-based tool for creating charts and graphs

- Data comparison - provides a method of easily comparing controller data to results from operator tests

Advanced Cooling Tower and Boiler Controllers

An eController from Watertech of America can take your water treatment control program out of the dark ages. These controllers have the latest, most advanced, cooling and boiler water control methods available on the market. That, combined with 21st century remote monitoring capabilities make this the best controller available on the market today.

Control Logic

Over the years many different methods of controlling boiler and cooling water systems have emerged. Many of these have become industry standards and are found in all of the leading controllers. The eController includes all of these industry standard controls plus many new, innovative options that have the ability to improve system performance. Some of the more advance features inclue:

ORP-based Biocide Feed

Typically oxidizing biocides have been fed according to weekly or monthly timer. The disadvantage of this method is that it does not respond to changes in your system. The same amount is fed regardless of what the true demand is. The result can be that you may be overfeeding (leads to wasting product) or underfeeding (leads to poor system performance).

The eController has the ability to monitor the Oxygen Reduction Potential (ORP) of your system. The ORP of your system can be related to the biocide demand which will then control how much biocide is fed into the system. The controller logic allows you to enter an ORP setpoint which it then maintains. This ensures that you always have the proper amount of product in your system. In addition, alarms can be sent to your operators when the ORP exceeds a high or low set point.

PPM Feed

Most methods of control assume that your chemical feed pumps are delivering the correct amount of product based on your system conditions. Now, with the newest version of the eController we can control you system based on the actual amount of product that is being delivered. It accomplish this we use an accurate, affordable flow meter that measure the actual amount of chemical that your pump is delivering. Measuring this volume allows us to enter the optimum feed rate into the eController. The eController then uses the volume of make up water to determine how much product needs to be feed. The chemcial feed pump is activated until that amount of product is fed. No other method of control provides this level of accuracy for feeding chemicals into a boiler, cooling tower or any other water system.