- Home

- Companies

- Bluewav Technology Co.,Ltd.

- Products

- Bluewav - Model BWT-10K - water ...

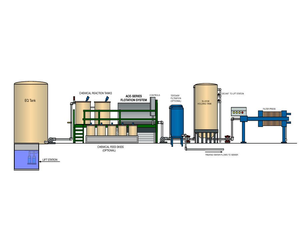

Bluewav - Model BWT-10K -water treatment system in Slaughterhouse

Designed exclusively for the unique challenges of slaughterhouse wastewater, our Slaughterhouse Water Treatment System delivers reliable, cost-effective, and regulatory-compliant purification to address high concentrations of organic matter, fats, oils, proteins, and suspended solids—common pollutants in slaughtering and meat-processing effluents.Ideal for all scales of slaughterhouses (bovine, porcine, poultry, and aquatic) and meat-processing facilities—from small-scale local plants to large industrial complexes. It adapts to variable wastewater volumes (50 m³/day to 5,000 m³/day) and fluctuating pollutant loads, ensuring consistent performance even during peak production periods.

1. High-Efficiency Pollutant Removal

Equipped with a multi-stage treatment process (including screening, grit removal, anaerobic/aerobic bioremediation, and advanced filtration), the system effectively reduces BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), and TSS (Total Suspended Solids) by over 95%. It also targets and breaks down fats, oils, and greases (FOG) that often clog conventional systems, ensuring long-term operational stability.

2. Full Compliance with Environmental Standards

The system meets global regulatory requirements for wastewater discharge (e.g., EU EIA Directive, US EPA standards, and local environmental bureau regulations). Treated water can be safely discharged to municipal sewers, reused for non-potable purposes (e.g., equipment cleaning, yard irrigation), or further polished for higher-recovery recycling—helping your facility avoid fines and build a sustainable brand image.

3. Durable & Low-Maintenance Design

Constructed with corrosion-resistant materials (304/316 stainless steel, FRP) to withstand the acidic/alkaline nature of slaughterhouse wastewater, the system requires minimal manual intervention. An integrated PLC control panel enables automatic monitoring of key parameters (flow rate, pH, dissolved oxygen) and alerts, reducing labor costs and downtime.

4. Cost-Effective Operation

Optimized energy consumption (e.g., energy-efficient blowers for aeration) and low chemical dosage requirements lower daily operating costs. Additionally, the system can recover valuable byproducts (e.g., concentrated sludge for organic fertilizer production) to create secondary revenue streams for your business.

We provide end-to-end support, including on-site wastewater analysis, custom system design, professional installation, operator training, and 24/7 after-sales maintenance. Our team of environmental engineers works closely with you to optimize the system for your specific needs, ensuring maximum efficiency and compliance.

Choose our Slaughterhouse Water Treatment System to protect the environment, meet regulations, and enhance your facility’s operational efficiency—today and for the future.