Transcend Cleantec - Wedge Wire Screen

Wedge wire screen is a type of purifying screen, which is composed of profile wires and support rods. The profile wires are usually triangle wire and the support wire of wedge wire screen can be triangle wire, round bar, flat wire or wedge wire. Wedge wire screen has various types and specs. The type of wedge wire screen is mainly according to the shape of the screen. There are many types of wedge wire screens.

Main types are as follows-

- Wedge wire screen panel

- Wedge wire screen tube

- Wedge wire screen cylinder

- Wedge wire screen support grid

- Wedge wire sieve bends

- Wedge wire nozzles

- Wedge wire screen basket

- Wedge wire lateral assemblies

Wedge wire screen with cylinder panels and nozzle shapes is commonly used in the mine, coal, chemical and water treatment for filtering and screening.

Common Advantages of Wedge wire screens are-

- various shapes

- Various applications

- Accurate specs

- Strict inspection

- Perfect package

- Short delivery time

Wedge wire screen is prepared with profile wire, woven or welded and support rods. Accordingly, it can distribute into two major types: woven wedge wire and welded wedge wire.

From two basic forms, almost all shapes and sizes can be developed according to the customer`s wish, namely:

- slot tubes;

- flat screens.

The filter elements can be provided with fastenings, reinforcements.

In most of these cases a drawing will be submitted to the customer for approval. After welding these accessories to the filter elements, further treatment can be provided to improve the surface quality:

- degreasing and pickling (standard);

- hardening mainly by tenifer treatment and hard chromising;

- mechanical and electrolytical

What Are Slot Tubes?

Trislot slot tubes are composed of a surface profile that is spirally wrapped around axial support profiles and attached to each other by resistance welding. These filter elements have the unique advantages of very accurate, narrow, slot openings and perfect roundness all in one. Slot tubes can be provided with the necessary end pieces for attachments and/or reinforcements.

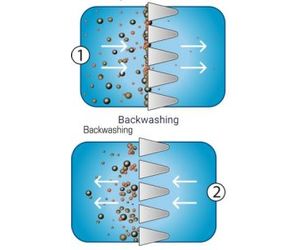

Filter cycle

- During the filter cycles the solids are deposited on smooth surface-

- This `cake` acts as an extra filter for finer particles.

- The fines that sleep through do not get stuck in the conical slots.

Backwashing

- Back wash cycle

- By reversing the flow, the cake and din are removed from the filter surface.

Trislot welded screens can be used as flat filters or processed to make cylinders.

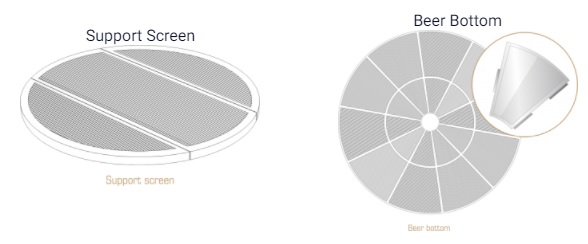

Flat Screens

- Static sieves for dewatering or classification: the screen is set up at a curtain angel or is curved so that the surface profile are perpendicular to the filtration direction. Through gravitation the slurry flows over the screen.

- Vibrating screens, dryers and coolers: screens used as support for the product that has to be treated.

- Band filters: screen as support for paper or textile, for example for the separation of cutting oil

- Support screens: in the application, the screens are assembled inside vesseles to support catalyst, active carbon, resin, molecular sieve...

- Beer bottoms

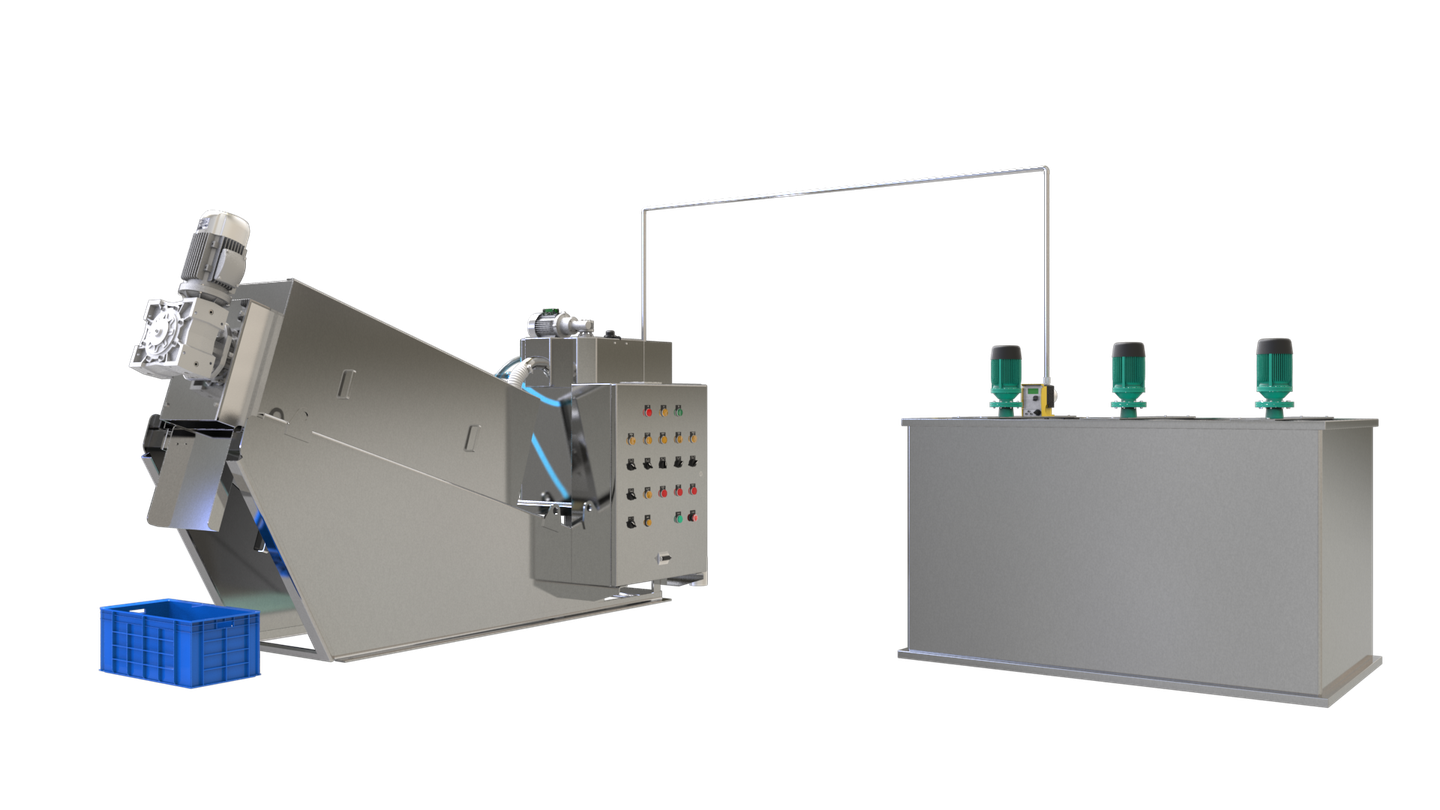

Cylinders and baskets

- Drum screens with or without internal transport screw.

- Centrifuge caskets and cylinders for the food and paper and pulp industry.

- Starch screens

- Screw presses

Curved Screens

- Curve direction and filtration Direction are to be determined by the customer.