WSAC - Wet Surface Air Coolers

The WSAC system is one of the most efficient and durable evaporative coolers available.

Some examples of cooling applications are:

Cooling

- Water

- Glycol

- Oil

- Fuel

- Gases

Condensing

- Steam

- Ammonia

- Propylene

- Butane

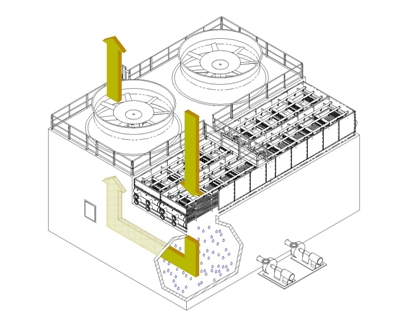

- Air is induced downward over tube bundles

- Water flows downward along with the air

- Heat from the process stream is released to the cascading water

- Vaporization transfers heat from the cascading water to the air stream

- The air stream is forced to turn 180° providing maximum free water removal

- Fans discharge air vertically at a high velocity to minimize recirculation

The WSAC system is one of the most efficient and durableevaporative coolers available. A WSAC system can cool a process fluid to within 5oF of the surrounding wet bulb temperature.

The wet bulb temperature is the lowest temperature that can be obtained by evaporating water into the air. The wet bulb is determined by a combination of relative humidity and ambient air temperature. For example if the relative humidity is 60%, and the ambient air temperature is 70oF, the corresponding wet bulb temperature is 61oF. Over the past 100+ years, Niagara has mastered the art of designing each cooler specifically to the needs of each application.

Liquid cooling

- Up to max inlet temp of 180°F

Single phase gas cooling

- Up to max inlet temp of 450°F

Turbine exhaust vacuum steam condensing

- As low as 1.8” HgA min

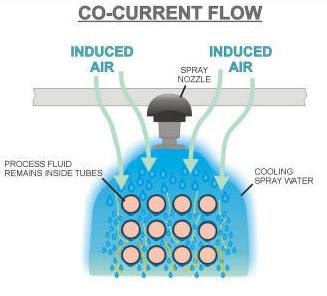

The WSAC cooler or condenser operates with induced draft co-current flow, which means that the air and spray water are both traveling in a downward direction across the tube bundle. This configuration ensures that spray water is evenly distributed over the entire tube surface and essentiallyminimizes the risk for fouling.

Other cooling methods use a counter-current flow, (air traveling up and spray water traveling down). This creates turbulence on the bottom of the tube. This turbulence results in incomplete distribution of the spray water over the tubes, which leads directly to fouling of the tube surface and a drop off in thermal performance.

As the cascading spray water mixes with the air, an equilibrium temperature forms as the water evaporates to the air, thus the warmed air and water mix together in the plenum/basin area providinginherent freeze protection during operation. Heaters can be included for non-operational cycles.

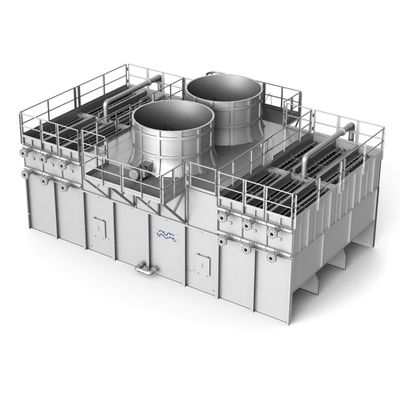

Niagara offers two variations of WSAC systems. All metal work is fabricated at the factory in Buffalo, NY.

Prepackaged Niagara units, like the one pictured above, is designed as a single skid with no field assembly required. These units can be shipped directly to the job site for easy and immediate installation.

Field erected units like the one pictured above are the largest design type Niagara offers. Constructed using either concrete or FRP (Fiberglass Reinforced Plastic), field erected Niagara units offer the ability to cool high volumes of process fluid in a smaller plot area (footprint) than a traditional cooling tower. Observation and maintenance of the spray water distribution system can be accomplished without structure entry, fan shut down, or pump shutdown, providing 24 hour operation. Access doors and hatches also allow for cleaning and inspection of the lower water basin.

Custom Designed

Niagara engineers have been providing cooling solutions for over 100 years for a wide variety of clientele. Each WSAC cooler or condenser is custom designed to fit a particular application. Design parameters are based on customer specifications for input and output temperatures as well as average weather conditions. All WSAC units are tailored to meet the unique needs of the most demanding applications in the world.

Applications for WSAC closed-loop, evaporative coolers and condensers

Liquid cooling

- Water/waste water

- Mold-water

- Glycols

- Food products

- Oils

Gas cooling

- CO2

- Natural gas

- Air

- Nitrogen

Vapor condensing

- Steam

- Ammonia

- Hydrocarbons (Propane, Ethane, Propylene)

System specifications

- Packaged

- Modular

- Field Erected

WSAC® systems are best applied for operations that will benefit from a leaving temperature of the process stream that is lower than can be reached economically by a cooling tower system. We have installations that provide exit temperatures below 80°F in extreme summer climates where cooling water can not provide this performance.

In the steel industry, we serve B.O.F. cooling, continuous caster water cooling, coke oven by-product cooling, benzene suppression, oil cooling, steam condensing, waste water biological treatment temperature control, and various water cooling duties.

In the chemical processing industry, we condense hydrocarbons and cool many process streams.

In the food industry, we provide cooling and condensing of organic vapors and cooling of process water streams.

In the pulp and paper industry, we provide vacuum condensers for black liquor recovery.

In the power industry we provide turbine steam condensing, thyristor cooling for long range transmission and general water cooling.

In general industrial applications, we provide furnace cooling, closed re-circulating water cooling, hydraulic and lube oil cooling, compressor jacket cooling, evaporative condensing, and compressed air cooling. These are a few of our more successful applications but we are in no way limited by the above list.

Electrical - Our electrical capabilities are all part of the package, and far exceed our customer`s expectations. We support our customers` specific electrical specifications needs, handling everything from control panels to aftermarket retrofits, and whatever falls in between. We cater to our Wet Surface Air Cooler (WSAC®) customers and their complex engineered-by-design units, as well as our Kathabar customers, which require the same solid expertise, and attention to detail we are recognized for. We are here to help - our capabilities are endless!

Control panels:

- Niagara/Kathabar standard controls

- Projects with no customer specifications

- Designs are safe, cost effective, and reliable

- Customer specification controls

- Projects with full or partial customer specifications

- Quoted, designed, and built to specification

PLC capabilities:

- Our PLC capabilities are limitless, please specify at time of quotation.

- Niagara/Kathabar standard PLC`s include:

- Allen Bradley

- Siemens

- Automation Direct

Certifications in which we design and build to:

Niagara/Kathabar builds to customer specification and has experience with but is not limited to the following:

- UL, cUL, CSA, ATEX, IECex

- Domestic and international hazardous area installations (Class I Divisions I and II or equivalents)

If you have specific needs please contact us to discuss your project.

Instrumentation:

Niagara/Kathabar uses electrical instrumentation that keeps cost down while providing reliability as a standard, but we are capable of using any customer specified instrumentation. Please specify your needs at time of quotation.

Quality control:

All control systems are fully tested in the factory to assure efficient installation and commissioning by our qualified technicians. Niagara/Kathabar will work with your specific quality needs and documentation upon request.

Pre-wiring: (small fabricated units -big value add to customers)

Niagara/Kathabar can wire all electrical components to a pre-mounted control panel or junction box to save wiring in the field. If this sounds like something you are interested in, please inquire at time of quotation. (Note that for larger equipment that ships in pieces, prewire may not be feasible)

Aftermarket retrofits and customer support:

Niagara/Kathabar supports all legacy installations of equipment. In the event that electrical instrumentation and controls become obsolete and replacement is needed we are here to help you and can retrofit all instrumentation and controls to our current standards as needed.

Heavy duty construction

The Niagara Wet Surface Air Cooling systems (WSAC) are designed and built for rugged and long lasting industrial applications. Niagara uses heavy gauge steel construction which is double brake flanged on all four sides and welded in all corners providing extreme rigidity, extended service life and durability. All metal fabrication is completed and tested in Buffalo New York before shipment to the job site.

H.D.G.A.F

Standard Niagara units are Hot Dipped Galvanized After Fabrication (H.D.G.A.F) according to ASTM A123. Zinc provides 42% more fighting resistance to rust and corrosion versus raw exposed steel. Dipping insures that all surfaces and machined edges are well coated. Niagara`s competitors use mill galvanized material which results in a significantly thinner layer of zinc and less protection against material degradation.

Alternate material construction

Since Niagara engineers every job from scratch, almost any material can be specified. Niagara offers optional 100% stainless steel construction and thick walled tubes for maximum protection and service life. Other materials include titanium, brass, copper, and more.

Custom Tube Bundles

Niagara WSAC systems are “closed-loop” which means that the process stream being cooled or condensed is never exposed to ambient air where airborne matter can contaminate it. Cooling tubes can be designed either in a serpentine or straight through and cleanable bundle depending on service requirements.

Tube bundles can sustain an operating pressure of 2500psi and can be designed in accordance with ASME code standards with all materials in contact with the process stream having full ASME material certification. Existing piping can be arranged and valved so that any tube bundle can be taken out of service for maintenance while the unit is operating.

Poor quality makeup water

With the growing concern of water usage, Niagara WSAC systems can use poor quality water as spray to reduce fresh water consumption. Typical examples of water sources include blowdown from existing cooling towers, wastewater, river water, pond water, etc. Wide tube spacing in conjunction with low pressure/high volume nozzles allows spray water to be run at high cycles of concentration, up to 50 cycles in some cases, thereby reducing water consumption up to 70% annually.

High efficiency fans

All fan assemblies are designed to give maximum fan efficiency and long life when handling saturated air at high velocities. A WSAC unit is sized to reject heat at the most difficult condition: full heat load at the highest expected wet bulb air temperature. Most WSAC fans operate in on or off modes with the fans automatically switching Off when the process outlet temperature begins to drop. Individual blades are adjustable pitch and can be either cast aluminum or FRP. Fans smaller than 5 foot diameter are directly connected to marine duty, Totally Enclosed Air Over (TEAO) motors. Fan greater than 5 foot diameter fan utilize TEFC, NEMA approved motors with fiberglass reinforced epoxy fin blades. Fan stacks are installed with access doors for system maintenance and inspection.

Accurate temperature control

Changing the air flow rate over the tube bundles very effectively controls the fluid outlet temperature. Multiple fans operating in parallel are used to induce the required air volume needed to evaporate the application’s heat load (as opposed to a single large diameter fan). This allows utilization of a number of different process temperature control schemes.

Variable Frequency Drive (VFD) fans can be used to increase or decrease the air flow rate depending on the process outlet temperature. The precision of a VFD is greater than the on/off scheme and can maintain outlet temperatures at +0 / -2.5 degrees F relative to the set point. VFDs can reduce the air rate automatically when the process outlet temperature begins to drop due to lower heat loads or reduced wet bulb temperatures.

Simple RTD monitoring of outlet fluid temperature can be combined with logic control so to effectively modulate heat rejection capacity of the WSAC. Inlet vs. outlet temperature monitoring (delta T – cooling range) can permit capacity control functions to further improve response times relative to the set point.

Induced Draft

The Niagara units are induced draft co-current flow. Because of this arrangement, the pressure inside the casing and coil section is negative. Negative pressure is the best way to uniformly distributing of air over the tube bundles. The co-current flow (air and spray water traveling in the same direction) also insures proper distribution of the spray water over each tube. In counter-current flow, turbulent spots on the tubes prevent water from covering the entire tube surface. This causes hot spots that lead to deposits and scaling, thus affecting performance over time. Niagara’s high velocity discharge prevents recirculation of moist air back into the inlet of the unit. Additionally the Niagara arrangement does not require drift eliminators. Since there is no pressure drop across the drift eliminator section, as much as 15% less fan energy is required.

High velocity discharge

Niagara discharges the saturated air at high velocity to prevent recirculation back to the inlet of the unit. Even with a high discharge rate, Niagara’s tube bundle and fan arrangement does not require drift eliminators. This is due to the two 90 degree turns the air is forced to make before being exhausted. Most of the water drops out of the air-stream before it reaches the fans. Since there is no pressure drop across the drift eliminator section, as much as 15% less fan energy is required.

Drenching spray system

Spray water distribution employs a low pressure high flow design with full flood spray pattern to provide optimum tube bundle drenching. Inspection and service of the spray nozzles can be accomplished without removing any appurtenances while the equipment is in operation. Access packages and walkways are available from Niagara to further assist maintenance personnel with nozzle and bundle inspection. The spray system will also be arranged so that an individual tube bundles may be hydraulically isolated for service or control.

Hardware

Niagara construction employs drill through holes with nut and bolt fasteners. Drill through hardware sustains a much longer service life versus self tapping metal screws.

Low energy usage

The co-current design of the Niagara WSAC system does not require mist eliminators to remove the water droplets from the discharge air stream. Mist eliminators increase the static pressure load by approximately 15%. This increased pressure drop requirement directly equates to higher power consumption. The Niagara WSAC cooler or condenser also has a lower unit profile which reduces the spray water pumping head requirement by approximately 20%.

Benefits:

Why a Closed-Loop Cooling System?

- When open-loop cooling tower water is exposed to airborne contaminants (dust, dirt, algae/biological organisms), it is then transported to the heat exchanger, where fouling can jeopardize proper heat transfer performance

- Closed-loop recirculating coolantcan be aqueous glycol solution, which assures that freezing will never occur anywhere within the closed-loop.

- WSAC systems can still be located remotely from the intercooler/facility.

- Open-loop water on the WSAC system is virtually freeze proof. Only when zero load conditions exist can there be any freezing. This is easily protected against using small immersion heaters to maintain a demand-ready system.

- Temperature control using closed-loop is more assured. Simple RTD monitoring of outlet fluid temperature can be combined with logic control of fans to effectively modulate heat rejection capacity of the WSAC unit. VFDs can be supplied for even better temperature set-point control during fluctuating ambient conditions. Inlet vs. outlet temperature monitoring (delta T – cooling range) can permit capacity control functions to further improve response times (set point control). By contrast, cooling tower (CT) temperature control is more temperature-range limited with higher transient response times due to large volume of water in the circulating loop. Fan control will only be effective at capacity control at high-range of wet bulb conditions. At low ambient conditions, a CT will still evaporate a certain percentage of water even with fans cycled off. Thus, the water temperature will continue to ramp down if not balanced by heat load from the plant. Complete tower bypass yields pump head inefficiencies unless VFD control of pumps is provided. Freeze protection of CT loop is large concern due to large volume of water contained in the system. KW consumption may become copious to maintain a thawed basin condition.

- Closed-loop, evaporative coolers consume less parasitic energy that CT for same heat rejection. Typical fan horsepower reduced by 10-25%. Typical pumping horsepower reduction of 10-40%.

- Water savings. : WSAC systems can operate at higher cycles of concentration leading to lower make-up and blow-down rates. This represents best use of water for facility water balance. WSAC systems can be designed to allow cooling capacity without evaporation of water (wet/dry system). Finned tube bundles, spray water zone cycling are both viable options to consider. Water conservation is the big benefit of these upgrade options. This is not possible with a CT cooling system.