The ideal solution for inspecting road transport for excess loading

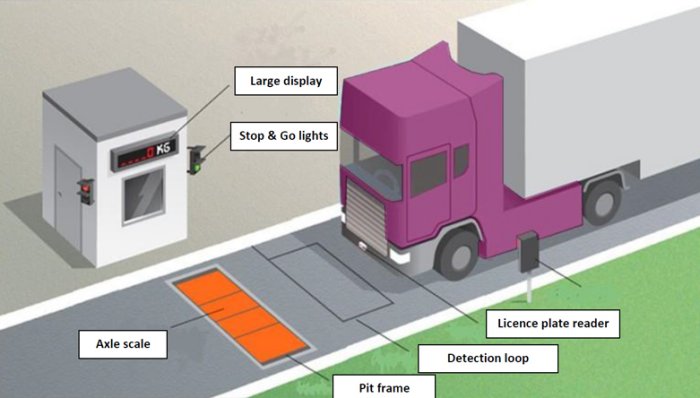

Sturdy tracks in reinforced sheet steel, made up of modules sized to withstand any load on the basis of the parameters laid down by the 96/53/EC Directive (laying down maximum axle loads for vehicles transiting in Europe).

STERELA, a company specialising in High-Speed Weigh-In-Motion (HSWIM) systems, has teamed up with Dini Argeo, an Italian company specialising in the design and construction of weighing scales and systems, to offer you RWS platforms, a product using innovative technology designed and created specifically for Low Speed Weigh-In-Motion (LSWIM) missions.

RWS platforms can be used in all situations where you need a rapid and simple solution for weighing vehicles such as trucks with 2, 3, 4, 5, 6 or more axles, tankers, container-transporters, etc.

A robust platform in reinforced metal sheeting, particularly suitable for the installation of fixed weighing stations to calculate the weight of vehicles in motion, by adding together the loads on the different axles, in dynamic-weighing mode.

The platform is designed for flush-floor embedding in a specially prepared area 36 metres long.

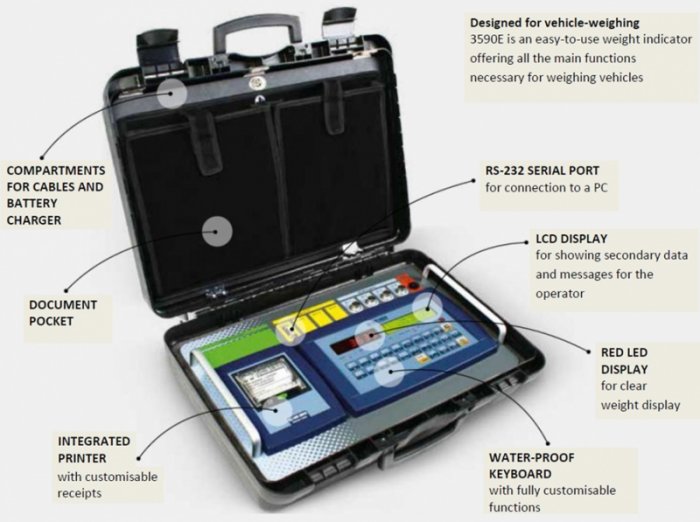

WEIGHT INDICATOR 3590E "AF09"

The 3590E weight indicator, in the "AF09" version, is designed for in-transit vehicle-weighing systems.

The indicator has two sets of functions:

- Vehicle weight detection, with printouts of axle weights and total weight.

- Accumulation of axle weights with the in/out function, plus memory of previous weighings via the ID code or the vehicle`s licence plate.

Two programmable digital inputs and four outputs are also supplied as standard, for automated operation, managing barriers or lights, etc.

It is important that all weighing data be archived for full traceability of operations performed.All data are available in Excel format; more than 5 million weighing operations can be stored.

USB MEMORY STICK FOR SAVING WEIGHING DATA TO A PC

RED LED DISPLAY for displaying total weight.

BACK-LIT LCD DISPLAY showing the weight of each platform and the centre of gravity.

FULLY CUSTOMISABLE RECEIPT.

CHARACTERISTICS

- Sandblasted and varnished with bi-component epoxy coating, highly resistant to corrosion.

- Dimensions of load-bearing area (l x w): 3 x 0.73 m.

- Six IP68-protected load cells in stainless steel.

- 10-metre cable for connection to a weight indicator.

- Dustproof and waterproof wiring and connections.

- Waterproof junction box.

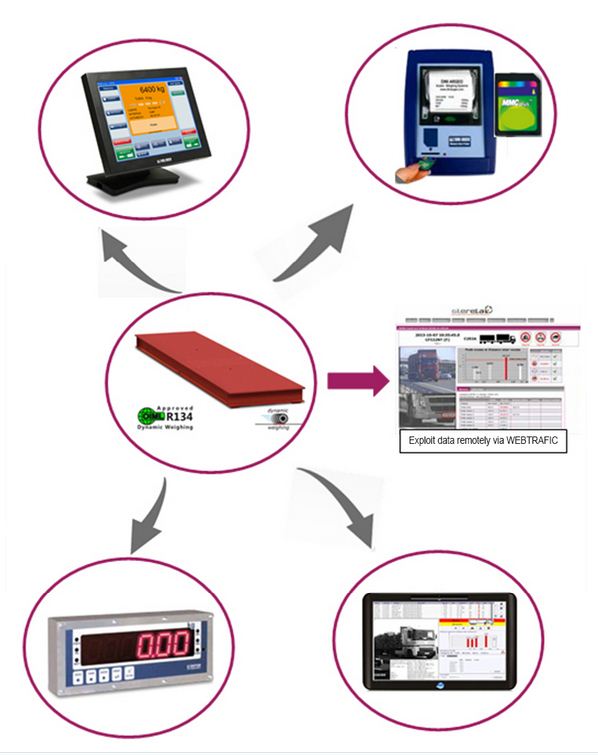

- A wide range of weight indicators are available, from touchscreens to simple in/out indicators. Battery-operated weight indicators also available (with transport case) to enable the RWS to be used without any mains power supply.

- Maximum transit speed: 5km/h.

FEATURES

- Vehicle weighed by totalling the weights of each axle (dynamic axle-weighing mode) with only a single RWS platform and the sum of all the axles.

- The weight of each axle can be detected manually by pressing a button when the axle is stationary and correctly positioned on the platform, or automatically when the vehicle transits over the platforms.

- In/out weighing for calculating and storing the weight of the goods transported by vehicles entering or leaving a company or site.

- Three levels of total, which can be printed and reset to zero separately:

- weight of each axle,

- total of current vehicle,

- total of vehicles weighed, (plus the overall total).

- Managing the vehicle’s unladen weight.

- Archives of data compiled manually by the operator (licence plate, product transported, customer, supplier, etc.).

- 1000 files archived, with programmable password for changes, each consisting of 5 alpha-numerical descriptions, for managing vehicles, customers and products.

- Alibi memory for use during regulatory use of the system.

OPTIONS

- Well frame casing for embedding the RWS platform, consisting of a structure in painted, welded steel, requiring no assembly.

- It facilitates embedding and simplifies engineering work.

AVAILABLE VERSIONS :

Model - Max (kg)

RWS15T: 15 000

RWS25T: 25 000