- Home

- Companies

- Fransgård Maskinfabrik A/S

- Products

- Fransgard - Model W / W-EH-Series - ...

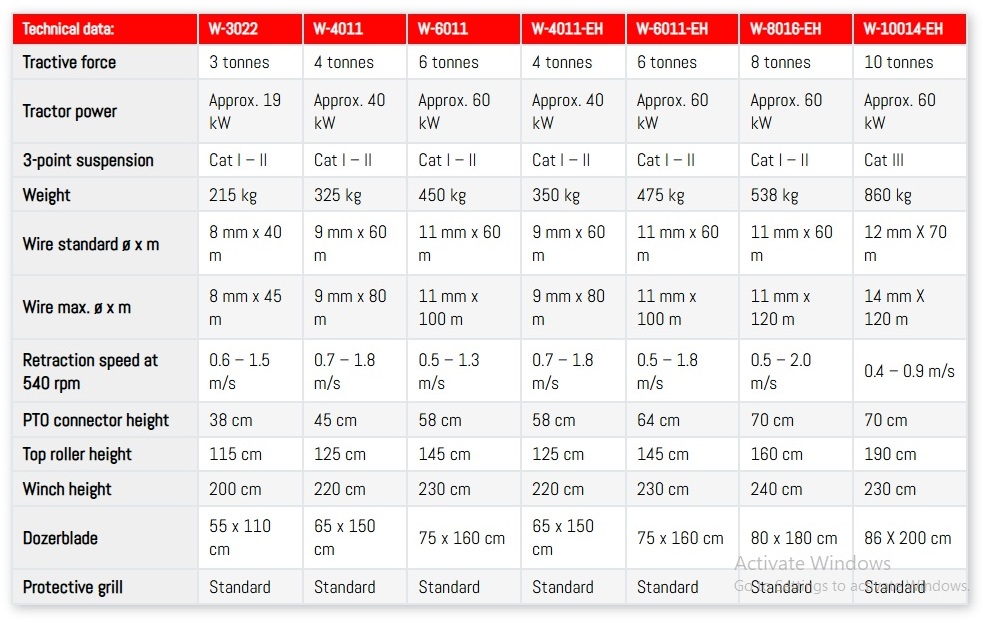

Fransgard - Model W / W-EH-Series - W-3022/W-4011/W-6011/W-4011-EH/W -Winch

The Fransgård W- model winches are mechanically operated and the W-EH models are hydraulically operated high-quality winches. The winches can be expanded with many great and functional details that facilitate the workflow, such as a chainsaw holder, built-in toolbox, removable towbar and much more. Everything is designed to be simple and durable. Our hydraulic models (EH) must be operated by a cable control or wireless remote control and can be fitted with a hydraulically controlled top roller to assist with the unwinding of the wire.

Backplate

The backplate protects vital parts from foreign objects and helps provide an extra stable main frame.

Towbar fittings

The W models are prepared as standard for the installation of towbars, item no. 1518.

Belt brake

All W-winches are equipped with a belt brake around the drum, which ensures that the drum is always braked and cannot run back when you stop winding the wire.

Bottom roller

A rotatable bottom roller on the winch provides greater safety when winding in from an oblique angle while moving the centre of gravity lower, minimising the risk of being lifted and allowing the use of a smaller tractor. The bottom roller is enclosed to ensure that the wire cannot jump off the pulley when you stop the pulling.

Freewheel brake

The wire drum is fitted with a spring-loaded freewheel brake, which ensures that the wire drum stops rotating as soon as the extraction of the wire is stopped. This prevents loose wire parts from entering the wire drum.

Galvanised bolts

All bolts, tow pins and splitters are galvanised.

Green cord

The clutch is activated via the green cord on W models, while the brake is always applied in the same work function. The large gearing on the cord drive means that little effort is required when working with the winch. (W models)

Main frame, rear

The main frame in the rear is shielded all over.

Main frame, front

The main frame of W forestry winches is beautifully designed and made out of Domex 420 steel with many reinforcements.

Chain fall

The chain fall at the top of the dozerblade is standard equipment and built in high-strength steel Domex 650.

Storage boxes

Storage boxes for chains, stripper rollers, etc., are fitted as standard on each side of the winch.

Hanger for cord control.

2 hooks for hanging the cord for the cord control on all W winches.

PTO drive

The extra reinforced drive chain ensures long life and minimal wear on the gear wheels, as well as fewer breakdowns. The chain is lightly lubricated from the outside with chain spray or grease. It is important not to use oil, as it will run down the clutch lining, which is riveted to the large gear wheel.

PTO hook

Hook to position the PTO axle when the machine is not in use. It can easily be turned to the side while working with the winch.

PTO connector

The PTO connector is well protected and placed high on the winch to avoid an excessive angle on it during work.

Red cord

The brake is released by pulling the red cord. If the cord is pulled all the way to the stop, it is loosened and the wire can be pulled out.

Service hole

The galvanised cover plate turns down easily, and the large hole provides good working conditions when installing the wire lock or servicing the clutch cylinder on EH models.

Safety grill, up

All Fransgård winches have a safety grill as standard to protect the tractor during work.

Safety grill, down

The safety grill can easily be turned down in front of the winch without using tools, allowing a better view behind.

Dozerblade, end

The ends of the dozerblade/butt plate are reinforced and prepared for mounting extensions on both sides.

Dozerblade

The wide and high dozerblade ensures a stable construction and good fixed support when pulling in the wire.

Cord control

The cord controll on the W models has high gearing, so less force is needed to operate the winch. All parts are galvanised (not W-3014) and with the possibility to replace the pulley rollers.

Splitter

All ring splitters are suspended by chain so that they do not disappear when mounting the winch on the tractor.

Support legs

The 2 support legs are easily lifted up while working with the winch and are always there when it needs to be parked again.

Pulley rollers

Galvanised pulley rollers with nylon wheels provide reliability and long life.

Wire lock

The wire lock is galvanised and mounted on the drum so that it does not disappear when the wire is changed or pulled out of the drum.

Wire guide, top roller

The top roller in the cast steel box has a cast wire roller, which is fitted with 2 ball bearings and a wire guide with hardened steel bushing. The moulded top roller box rests on a support plate, which ensures stable wire retraction, even under heavy loads. The support plate can be greased so that the top roller turns freely from side to side. The W-EH winch can be fitted with a top roller with hydraulic extension, item no. 1550-14. (Not W-4011-EH).

Axe holder

Axle holders are standard equipment on all winches.

Brake cylinder

The brake cylinder of the W-10014-EH is fitted with an extra strong spring to ensure optimal braking effect.

3-pin connector

The power for the W-EH winches is taken from the tractor via the 3-pin connector.

7-pin connector

The 7-pin connector on the W-EH winches makes it easy to install cable control or radio control as required to operate the winches.

Accumulator

All W-EH winches are fitted with an accumulator on the hydraulic system.

Cable pullers

Cable pullers with 5 metre cable can be used for operation of the W-EH winch (optional extra item no. 1591).

Oil pump

The PTO driven oil pump is well protected inside the main frame and is driven by a powerful chain and gear wheel.

Oil tank

Robust and pressure-tested oil tank with dipstick ensures a supply to the winch

Radio receiver

The radio receiver from the radio controls can be mounted inside the tractor cab, and the 7-pin connector can be pulled out to the winch.

Radio

The hand-held transmitter on the radio controls can be used to operate the W-EH winches. Activation and deactivation of the brake, winding of the wire and unwinding of the wire (requires hydraulic wire unwinder, item no. 1550-14). The radio can also be connected to the tractor's horn and engine reversing system. (See optional extras for the models)

Oil pressure guage

The oil pressure gauge is mounted on the back of the W-EH winch, so it is easy to see if the hydraulic system has reached the desired pressure.

Valve block

The large aluminium valve block, which controls all W-EH winch functions, is well protected inside the main frame and can be easily operated by removing the front screen.

Brake cylinder

The brake cylinder on the W-10014-EH is equipped with an extra powerful spring to ensure optimal braking effect.