- Home

- Companies

- Emerson Process Management

- Products

- Rosemount - Model 2160 - Wireless Level ...

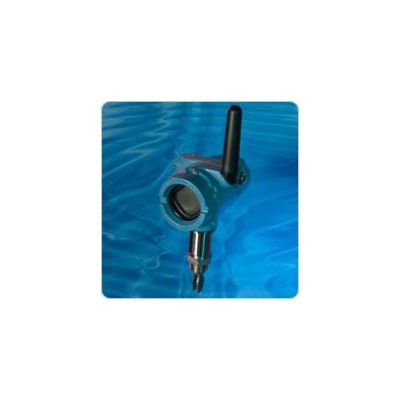

Rosemount - Model 2160 -Wireless Level Switch

The Rosemount 2160 Wireless Level Switch offers all the features of wired level switches without the complication and cost of wiring.

WirelessHART vibrating fork liquid level switch combines Emerson’s wireless expertise with the Rosemount 2100 series vibrating short fork technology. It has all the same features as the wired level switches in the Rosemount 2100 series, but without the complication and cost of wiring. Features include a complete range of process connections, aluminum housing, a choice of wetted parts materials, dry-to-wet and wet-to-dry switching functions, extended fork lengths, and hazardous area approvals.

The Rosemount 2160 continuously performs instrument health diagnostics of the fork and sensor. These diagnostics can detect external damage to the forks, internal damage to the sensor, excessive corrosion and over-temperature. The 2160 can withstand temperatures from -94 °F (-70 °C) up to 500 °F (260 °C) and pressures to 1450 psig (100 bar g).

The Rosemount 2160 wireless vibrating fork liquid level switch extends the full benefits of PlantWeb® to previously inaccessible or uneconomical locations due to the high cost of wiring in a wide variety of challenging applications.

The Rosemount 2160 has been TUV tested and approved for overfill protection according to the German DiBt/ WHG regulations. It is certified under safety devices for tanks and piping related to water pollution control.

Forms a true wireless level monitoring and control solution with the Rosemount 3308 wireless guided wave radar.

Features & Benefits

- WirelessHART capabilities extend the full benefits of PlantWeb® to previously inaccessible locations

- Designed for operation in temperature extremes of -94 to 500 °F (–70 to 260°C)

- Suitable for most liquids

- Virtually unaffected by flow, bubbles, turbulence, foam, vibration, solids content, coating, properties of the liquid, and product variations

- No moving parts or crevices means virtually no maintenance

- Electronic, enhanced self-checking and condition monitoring available via local handheld or AMS

- Adjustable Switching Delay for turbulent/splashing applications

- Small in size and weight, short fork length up to 118-in (3 m)

- "Fast Drip" Fork Design gives quicker response time especially with viscous liquids

- Intrinsically Safe certification option

- Self-organizing network delivers information rich data with >99% data reliability

- TUV tested and approved for overfill protection according to DiBt/ WHG regulations

Specifications

Approvals

Certification: Intrinsically Safe, and No hazardous area certification

Approved for overfill protection according to DiBt/ WHG regulations.

Certificate number: Z-65.11-518

Construction:

Housing: Aluminum

Wetted Material: 316⁄316L Stainless Steel (1.4401⁄1.4404) dual certified, or Alloy C (UNS N10002) and Alloy C-276 (UNS N10276)

IP Rating: IP66 to Type 4X

Antenna: PBT⁄PC integrated omni-directional antenna

Connections

Process Connection: Threaded, Flanged, or Hygienic

Electrical

Field Communicator Connections: Clips are permanently fixed to the terminal block inside the housing

Wireless Power Module: Replaceable, Intrinsically Safe Lithium-Thionyl Chloride power module with PBT enclosure

Functional

Output: WirelessHART 2.4 GHz DSSS

Local Display: Optional five-digit integral LCD display can indicate the switch state (Dry or Wet) and diagnostic information

Transmit Rate: User-selectable: from 1 second up to 60 minutes

Operating Conditions

Process Temperature: -94 to 500 °F (-70 to 260 °C)

Process Pressure: 1450 psi at 122 °F (100 barg at 50 °C)

Note: Extended lengths are available