- Home

- Companies

- WTP Equipment Corp.

- Products

- WTP - Model SL - Bar Screens

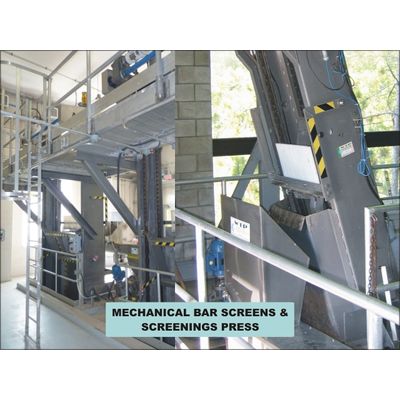

WTP - Model SL -Bar Screens

Front-cleaned, front-return mechanically cleaned reciprocating bar screens for wastewater screening having a stationary, rake-cleaned bar rack – no moving parts other than the rake are submerged, eliminating drive system fouling. Screen size, bar rack opening size, discharge height and channel dimensions are engineered to your specific application.

Anti-Fouling Design

Screenings, collected on a stationary front-cleaned bar rack, are removed by a heavy duty chain & sprocket driven traveling rake. No moving parts, other than the rake, are submerged at any time - chains & sprockets are located above the maximum liquid level. Drive mechanism fouling is eliminated and maximum corrosion protection is provided. Maintenance is done at the operating floor level.

Full Depth Cleaning

The cantilevered rake swings into initial engagement with the bar rack at the channel invert, scooping and lifting large quantities of screenings. Maximum screening efficiency is achieved because, during each cleaning rake cycle, the full depth and width of the screen bar rack openings are cleaned to prevent blinding by lodged materials.

Clean Discharge

At discharge the cleaning rake swings out. above and behind the deadplate apex, to ensure screenings are cleanly deposited into the discharge chute without material hang-up.

Long Service Life

Trouble-free operation is ensured by use of non-corrosive materials of construction -stainless steel and engineering plastics.