- Home

- Companies

- Xinyang Equipment Technology Co., Ltd

- Products

- Xinyang - Dual Motion Mixer

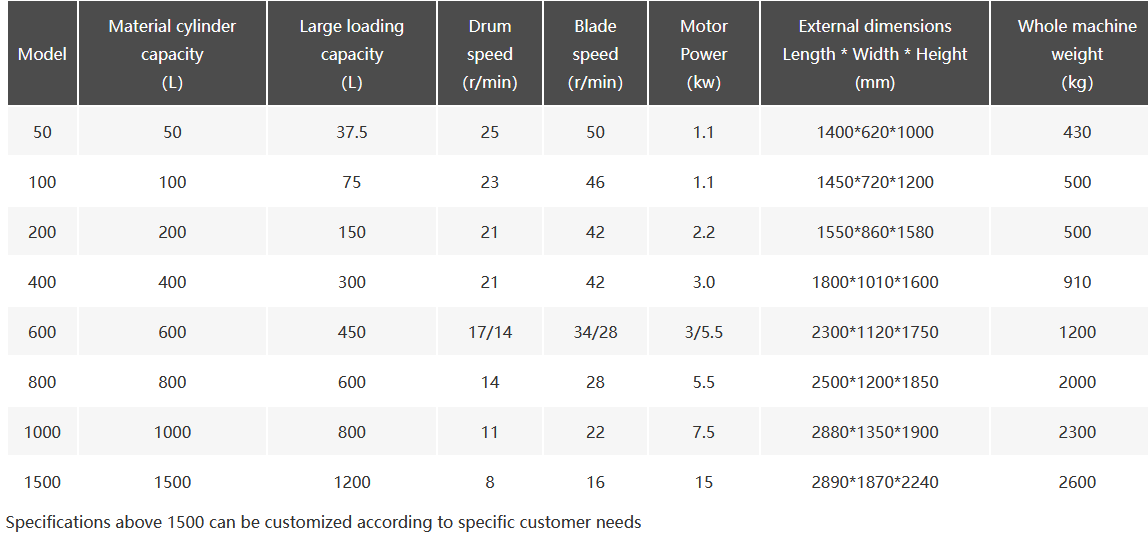

Xinyang - Dual Motion Mixer

The characteristic of the pharmaceutical and food type dual motion mixer model is that it has advantages compared to existing mixers on the market, achieving a high degree of mixing effect on powders. It not only achieves macroscopic uniformity of powders (uniform sampling of powders in the upper, lower, left, and right directions inside the barrel), but also microscopic uniformity of powders (uniform dispersion of powder particles between particles at the microscopic level).

The pharmaceutical and food type dual motion mixer is used in industries such as food, medicine, and additives. Compared with existing mixers on the market, this model has advantages in achieving a high degree of mixing effect on powders. It not only achieves macroscopic uniformity of powders (uniform sampling of powders in the upper, lower, left, and right directions inside the barrel), but also microscopic uniformity of powders (uniform dispersion between particles at the microscopic level).