- Home

- Companies

- Efficiency Scientific Instrument Co., ...

- Products

- ESI - Model EDX8800H MAX - XRF Nickel ...

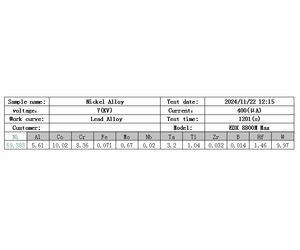

ESI - Model EDX8800H MAX -XRF Nickel Alloy Analysis Instrument

Nickel alloys are essential in modern industry due to their outstanding properties. They offer excellent corrosion resistance, enduring acidic, alkaline, and saline environments, making them ideal for chemical plants and petrochemical refineries. These alloys also excel in high-temperature strength and stability, crucial for aerospace and energy sectors. For example, they are used in aircraft engine turbine blades and nuclear reactor components to withstand extreme heat and mechanical stress. Additionally, nickel alloys are tough, resisting cracking and deformation. This, along with their conductivity and durability, makes them suitable for marine engineering, electronics manufacturing, and high-quality electrical connectors. The EDX8800H Max is a specialized device for testing nickel alloys.

1.Equipped with Peltier electric refrigeration, the FSDD silicon drift detector not only has excellent short-term reproducibility and long-term reproducibility, but also has excellent element resolution.

2.It can simultaneously perform element and oxide composition analysis.

3. The specially designed optical path and vacuum system greatly improves the test sensitivity and accuracy of light elements (Na, Mg, Al, Si, P). A helium gas system can also be optionally configured to directly test liquid and powder samples.

4. Eight kinds of optical path collimation systems, which automatically switch according to the size of different samples, can also test different positions of the sample and then take the average value, reducing the error caused by the non-uniformity of the sample.

5.High-definition built-in camera, clearly displaying the sample parts detected by the instrument.

Aerospace: Analyzes nickel alloy in turbine blades etc. for correct element proportion for high performance.

Petrochemical: Monitors alloy composition in reactors etc., detects corrosion-causing elements for equipment integrity.

Power Generation: Checks alloys in nuclear/gas plants, ensures stability under high heat and pressure.

Metallurgy: Determines alloy quality, aids in production process control and new alloy development.

Medical Device: Tests nickel alloy in implants and instruments for biocompatibility and quality.

Dimensions: 60mm*610mm*1040mm

Weight: 165Kg

Element Range:Na11-U92

Analysis content range:0.2ppm- 99.99%

Detector:AmpTek high resolution FAST SDD

DPP Analyzer: 4096 Channel DPP analyzer

Excitation Source:50W X-ray tube

HV unit:0-50kV

Power supply:220ACV 50/60HZ

Environment:-10 °C to 35 °C

>Standard

Ag- Calibration standard

Vacuum pump

Sample cup (Powder/Liquid)

USB cable

Power supply cable

Test Mylar

Calibration report

>Optional

Mill machine

Sample pressing machine

ESI-900automatic fusion machine

Fusing bead machine

Ten-thousandth accuracy balance

Mineral Standard samples

Power stabilizer

The principle of an X-ray fluorescence spectrometer is based on the interaction of X-rays with matter. When a sample is irradiated by high-energy X-rays or gamma rays, the atoms in the sample are excited. Inner electrons are promoted to outer orbits, creating vacancies. Outer electrons then transition back to fill these vacancies, emitting characteristic X-ray fluorescence with specific energies that are related to the element type. By detecting the energy and intensity of these fluorescent X-rays, the types and contents of elements in the sample can be determined.

The spectrometer has several advantages. Firstly, it enables non-destructive analysis. Valuable or rare samples like archaeological artifacts and jewelry can be analyzed without damage. Secondly, it can perform simultaneous multi-element analysis. Complex materials such as ores and alloys can have multiple elements detected at once, enhancing analysis efficiency. Thirdly, it offers relatively fast analysis. Simple samples can yield results in minutes or even seconds, which is beneficial for industrial quality control. Additionally, under proper conditions, it provides a certain level of accuracy, especially for major and high-content elements, making it a reliable tool for various applications in fields like materials science, environmental monitoring, and manufacturing.

Hot Tags: xrf nickel alloy analysis instrument-edx8800h max, China, manufacturers, suppliers, factory, buy, cheap, discount, low price, made in China, XRF Jewelery Tester, Oil Analysis Equipment, XRF RoHS Analyzer, XRF Plating Thickness Measurement, XRF Spectrometer, Portable Lube Oil Analyzer