- Home

- Companies

- Ningxia Yongruida Carbon Co., Ltd.

- Products

- Yongruida - Anionic Polyacrylamide

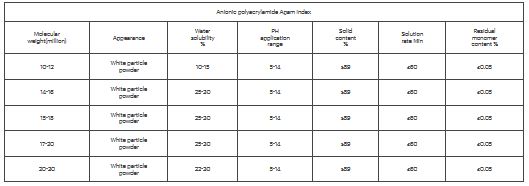

Yongruida - Anionic Polyacrylamide

Anionic Polyacrylamide is produced when acrylamide is polymerized with an anionic comonomer. Water soluble Polyacrylamide have been used for decades to facilitate solidliquid separations in wastewater and drinking water treatment, the pulp and paper industry, aquaculture, and many other industrial processes.

Today there are several anionic polyacrylamide -based products marketed for use in construction site sediment management. These products can be applied for erosion control, clarification of sediment laden runoff, and de-mucking of wet sediment during pond cleanouts. They are designed to be used in conjunction with other best management practices, as part of a multi-barrier approach, to minimize soil loss and improve settling of suspended ediments.

- Any anionic PAM product used for erosion and sediment control on a construction site should adhere to the following criteria.

- Anionic PAM is the active ingredient. Only products using water soluble anionic PAM as the active polymer ingredient should be used. Products containing a synthetic cationic polymer or chitosan should not be used due to their higher toxicity to aquatic organisms.

- Site Specific Performance Testing. The manufacturers of anionic PAM-based products typically offer more than one formulation of a given product, with different formulations varying in the relative amounts of PAM and other additives. Different formulations are designed to bind different soil types. Samples of water to be treated and sediment from the site should be tested with the various products and formulations available to determine which will be most effective for the desired application.

- High molecular weight. The anionic PAM used in the product should have a molecular weight between 6 and 24 mg/mol, with 12 to 15 mg/mol preferred.

- Emulsion forms of anionic PAM should be avoided.

- Residual acrylamide content less than 0.05%.